40

CONSTRUCTION EUROPE

DECEMBER 2013-JANUARY 2014

DEMOLITION

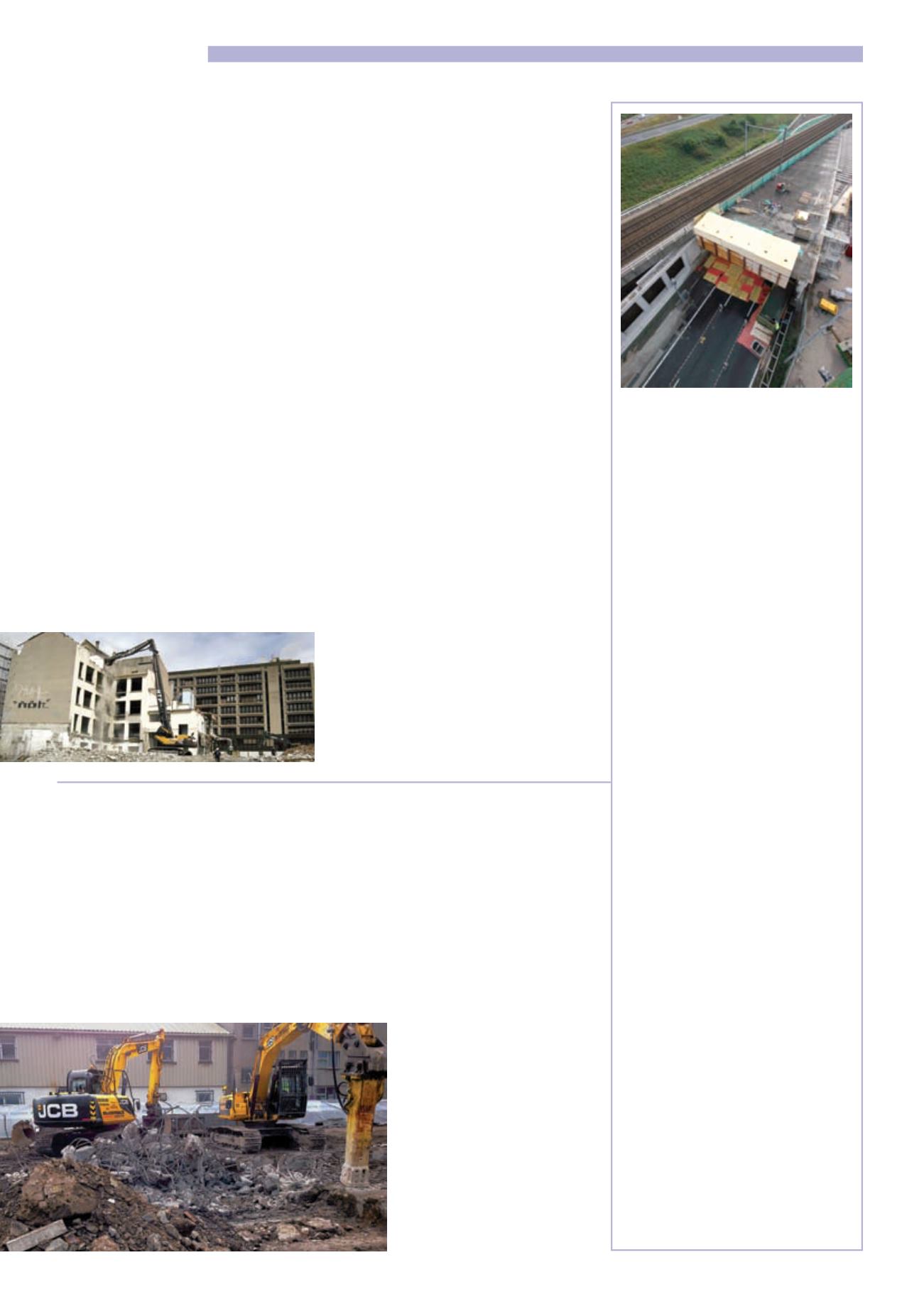

ADS used two Aquajet Systems Aqua

Cutter 710V evolution robots for the

Amsterdam project

Hydrodemolition

saving time

Existing elevated rail decking in the

Netherlands

presented

demolition

problems for the contractor BAM Civiel

in making ready for joining it to a newly-

constructed concrete deck and new twin-

rail track.

However, hydrodemolition specialist

Aqua Demolition Services (ADS) said it

was able to solve this when exposing the

steel cables to allow inspection before

connecting the new elevated concrete

deck and rail tracks in Amsterdam.

Fabricated some 20 years ago in

readiness for future expansion, the old

reinforced concrete deck – above the

busy A10 highway through the southern

suburbs of south Amsterdam – included

two post-tensioned cables.

After removing a balustrade/end wall

at one end of the old deck, using a

conventional concrete wire saw, it was

necessary to remove the deck concrete to

expose the rebar for reinstalling to the new

adjoining deck.

However, a bigger problemwas exposing

the post-tensioned cables for inspection

and recasing in new concrete, without any

damage whatsoever to the steel cables

and rebar.

ADS provided the solution with

hydrodemolition

techniques

using

two Aquajet Systems Aqua Cutter 710V

evolution robots.

ADS director Arjan de Waard said,

“Without using the Aqua Cutters, possibly

the only other solution would have been

to use hand lances – taking eight to ten

operators at least two weeks to clear all the

specified concrete safely.

“Using

Aquajet’s

hydrodemolition

techniques allowed us to complete the

job inside one and a half days including

set up times.”

Road traffic challenge

Tramlines, pedestrian pathways and a busy road

contributed to the problems for a Swiss project

T

he key challenges for a recent

demolition project in a main street in

Geneva, Switzerland, were a tramline,

pedestrian pathways and road traffic.

Construction and demolition company

HTP was contracted to demolish former

governmental offices at the front of the busy

Rue du Stand.

The demolition was set to create about

2,000m

3

of material, with some 900m

3

of this

to be crushed on site and reused for site

preparation and construction of the new

building. The remainder had to be taken away

for recycling, with only a small percentage

going to waste.

The Volvo EC480HR D-Series claims to be

unusual in the high reach demolition sector

as it is Stage IIIB compliant, meeting the

emissions requirements without having to be

fitted with an additional exhaust gas filtration

system.

Volvo said that HTP had ordered the high

reachmachine before even seeing the finished

product.

Yves Huguenin, founder and managing

director of HTP, said, “When we made the

decision to invest in the Volvo EC480D HR, it

didn’t actually exist. The engine was new in

terms of emissions, and the hydraulics had

been optimised, so we felt it was a good

machine for us and the right size.

“Now we have the machine on site, and I am

delighted with our decision.”

Noise restrictions mean HTP can only work

from 7am to 7pm with a one-hour shutdown

from 12pm to 1pm – but this is said to be less

of an issue with the Volvo high reach unit,

which is quieter than breaker machines.

Thierry Truffat, site manager for HTP, said,

“There is a protective screen for the operator

along the front of the four-storey building, but

this is only for small fragments and dust and

certainly wouldn’t keep out any large-scale

debris.

“This is a highly-controlled demolition

process, which requires precision and great

care. The machine enables us to conduct a

safe deconstruction with real efficiency and

high productivity.”

HTP began by taking out the windows,

electrical cabling and insulation. During this

phase it also had to deal with some asbestos

contamination, which required special

attention.

Volvo said that thanks to the high reach

machine, the team was able to made up for

lost time.

ce

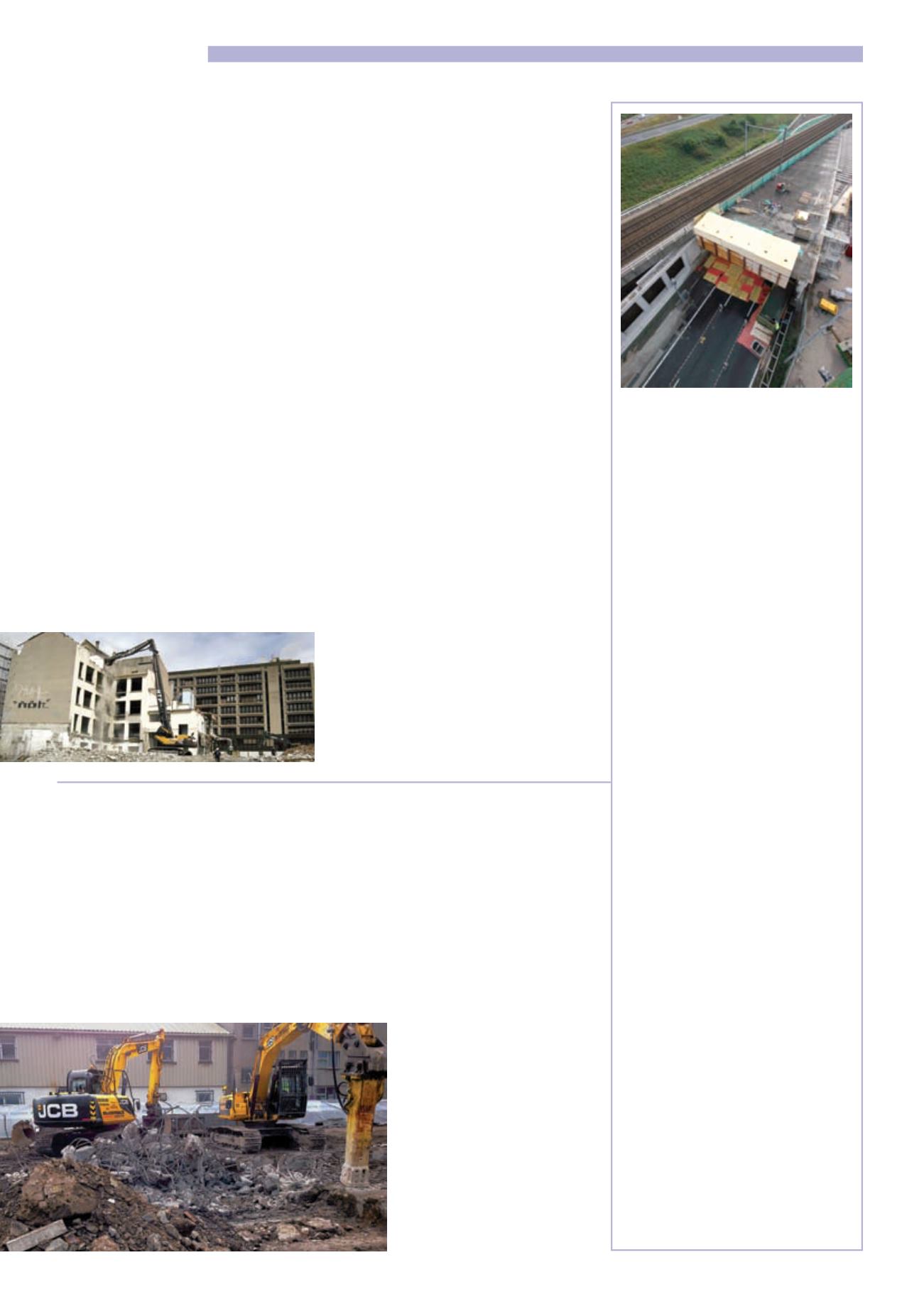

One of Northern Ireland’s leading demolition

contractors has been using a fleet of JCB

demolition excavators at a high-profile Belfast

project.

McCormack Demolition is currently using

JCB models at the new University of Ulster

Belfast Campus development – a £250m (€299

million) project at York Street adjacent to and

opposite the existing Belfast campus building.

The dismantling of existing buildings will

JCBs for university project

pave the way for approximately 76,500m

2

of new university space, and 6,500m

2

of

refurbished space to be constructed.

The McCormack fleet includes five JCB

models, with a JS360XD, JS330HRD and two

JS220 models recently joined by a new JCB

JS290XD.

Said to be tailormade for demolition, each

of the XD (Extra Duty) machines features a

strengthened boom and dipper, side and

rear impact protection, rugged

undercarriage

guards

and

plating, side rail protection

systems and FOPS cab guards.

McCormack director Eamonn

McCormack said, “We have

operated JCB excavators for over

20 years now, and the XD models

come ready for work. The new

models are super machines and

provide a robust solution.

“Our fleet of different sized JCBs

means we can match the right

machine to the requirements of

each job on site.”

ce