TRACK-MOUNTS

44

ACCESS, LIFT & HANDLERS

NOVEMBER-DECEMBER 2013

the Lightlift 17.75 Performance IIIS and

Lightlift 20.10 Performance IIIS with a 55-foot

and 65-foot (17 and 20 m) working height,

respectively.

“With the last two machines we have

increased capacity and they are much quicker,

compact and user friendly. Rental companies

also need reach and height, with, as in the

past, lower pressure on the ground with non-

marking tracks,” says Negri.

Both Hinowa machines offer 507 pounds

(230 kg) capacity, with up to two operators,

across the whole working area, a wide working

envelope at 24 feet (7.5 m) and 31 feet (9.7

m) continuous outreach for the 58 and 65

feet (17.75 and 20.10 m), respectively. The

machines are made of lightweight steel and

include bushings without grease designed for a

long life without lubrications - saving time and

money.

Rental gains

Gianpiero Marti, at fellow Italian manufacturer

BlueLift, thinks big rental companies will

embrace the tracked platform.

“For Scissors and self-propelled machines

rental rates are going down because there are

more competitors. The tracked platform will be

a way of moving out of this conflict and making

a profit.” Its latest model is the lightweight

58-foot (17.8 m) working height SA18. It offers

a 30.5-foot (9.3 m) outreach from a 9 foot by

9 foot (3 by 3 m) outrigger set up with one

person in the basket. It’s good for rental, the

company says, and can be transported on a

trailer.

As a result, BlueLift foresees tracked

platforms will make up 5 percent of the total

AWP market in the next three years.

But Palazzani’s export manager, Laura

Gasparini, is aware of the shortfalls of these

products. “The use of tracked platforms,

particularly the highest, requires the presence

of a specialist operator. So, Palazzani is

making significant innovations to its range to

make them easier to use than the previous

models, both in set-up phase and aerial work

operations.”

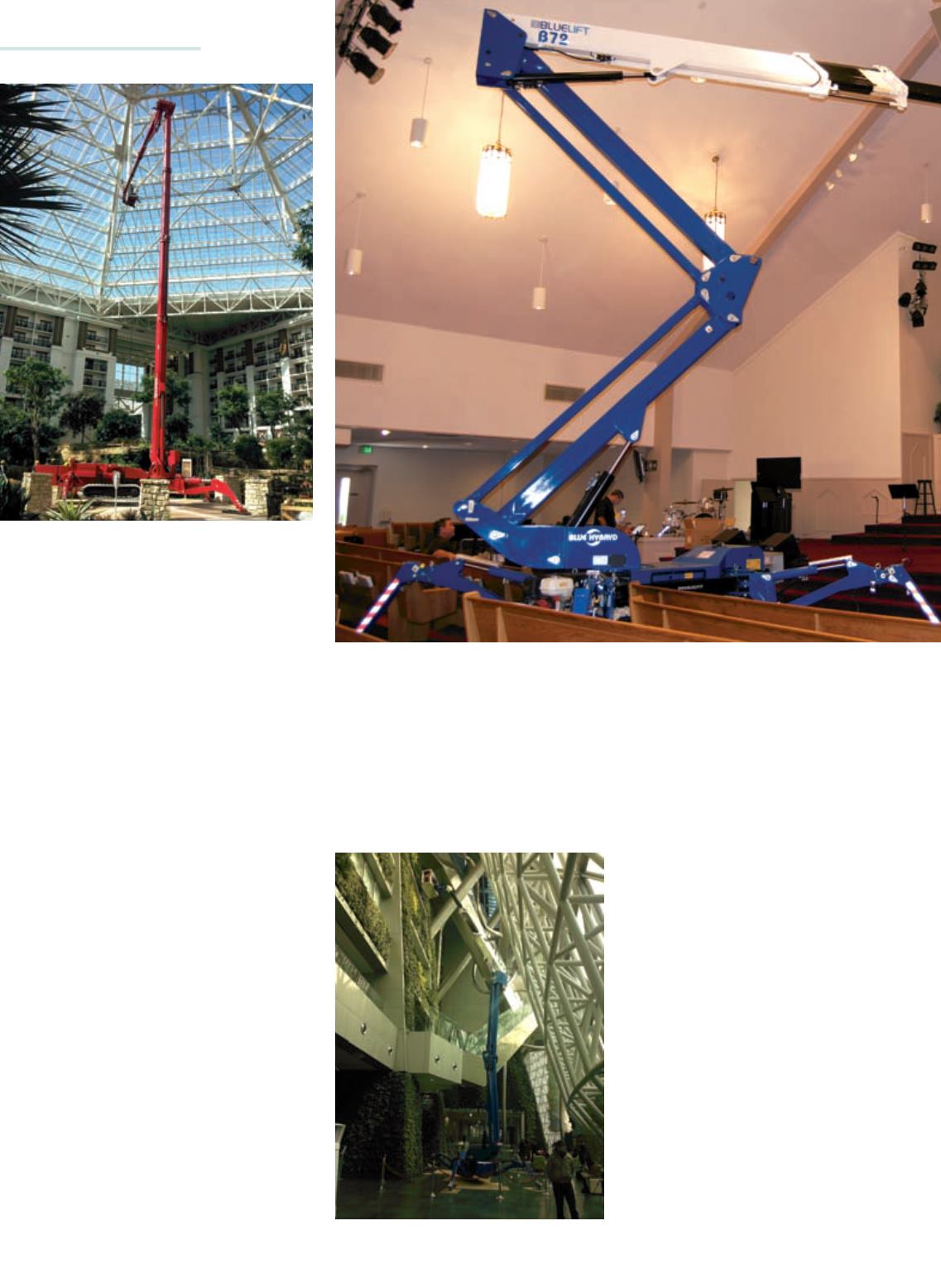

Ebbe Christensen, president of BlueLift

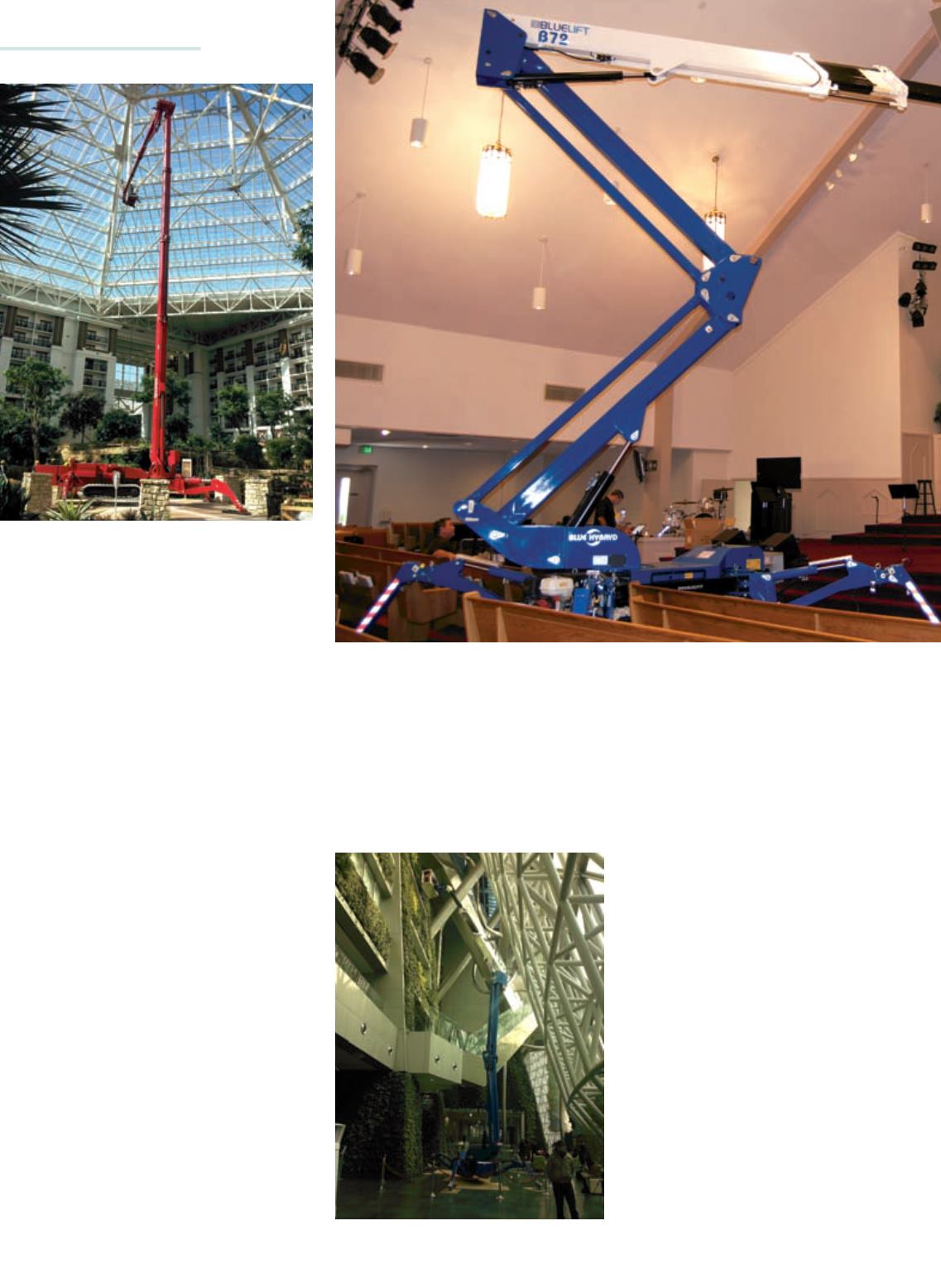

A ReachMaster Blue Lithium C22 at work.

A Tuepen LEO 40 GTX carries out high-end work.

and Falcon distributor ReachMaster, agrees.

“They are more nimble, more fragile; they do

take more training, because they have more

technology than booms or scissors,” adding,

“The secret behind a lot of those things is

CANbus; auto setting is certainly something

that is a big help, and safety features, for

example, if you change elevation while driving

by more than five degrees, the machine goes

down to half speed.”

Christensen adds, “I can has started to be

a major buyer in the U.S. because compact

39-foot to 72-foot (12 m to 22 m) track lifts

do all the things from a reach point of view of

scissors and booms in that range, but it’s a

much lighter, more versatile machine.”

“It’s almost like the tip of the iceberg – rental

have been reluctant because, but rental has

now finally seen that is easily outplayed by

gigantic applications being solved by other

machines in a less efficient and less safe way.”

Another general advantage, adds Christensen,

is delivery, where booms and often scissors

have to be delivered to site on multi-axle

trailers, tracked platforms can be transported

on smaller trailers.”

Some 50 percent of Reachmaster’s sales

currently go to rental companies. “I would not

be surprised if rental will become the most

dominant sector,” adds Christensen.

Great rental potential also lies in Europe says

Negri, “Since the recession rental companies

have been looking for alternative products, and