CONTROLLERS

>

The use of remote

controls is more

widespread than ever

in the AWP industry.

AI

reports

demand, more and more operators understand

the benefits of radio controls when it comes to

safety, efficiency and operating comfort.”

Safety message

Mr Silvestri expands on the point. “[The

standard] has recently introduced for the

first time requirements for the use of Safety

Radio Remote Control (SRRC) and control

systems. So we expect a growth of demand

for new EWP applications, as manufacturers

increasingly turn to safety electronics to

address these requirements.”

The selection of components to satisfy

the functional safety standards remains a

process requiring extremely careful analysis

for any OEM, adds Mr Silvestri. “A good

starting point is to look for control system

manufacturers that can demonstrate a long

track record of rigorous functional safety

certification with the most demanding bodies,

such as TUV.”

HBC’s latest innovation is the technos

2 and spectrum E radio controls.

They are ideally suitable

for the powered

access market.

Another launch

is the radiomatic

photon.This new

feature enables the clear

display of live camera

images on the radio control

and can work with several

cameras simultaneously. With

radiomatic report, a personalised login card

(HBC Smart Card) is the key to the system.

The card protects the control and machine

from unauthorised use, identifies the operator,

including their individual access level and

collects operational data on the radio control.

The data can be used to determine costs

accrued to those who rent the equipment.

Autec has launched the Supervised

Operator System (SOS), specifically

developed for AWPs performing live-line

work or other high-risk tasks.These systems

include a second supervisory transmitter

that allows a safety observer to continually

monitor the safe operation of the machine,

and intervene and take control in the event

of an emergency.The SOS system integrates

into the receiver a complete solution for

the supervised operation of the EWP.The

special receiver automatically manages the

two transmitters and passes commands to the

machine from the operator in control.

In the Dynamic series Autec

is currently launching the

compact ARX receiver,

specifically designed

for small to medium

hydraulic machines.

The company is also

designing a new series of

cabled control consoles

which will combine a

fail-safe emergency stop with

Åkerströms has become the main supplier to

Australian AWP manufacturer GMJ Equipment,

producing models from 10 to 70 m working heights.

“There are many advantages to using remote

controls,” says an Åkerströms spokesman, “such

as much better precision and a better overview,

since you can basically move without inhibition.

With the transmitter strapped around you there is

no tripping over cables or, as previously, having to

stand at a fixed point to control the object.”

GMJ uses dual transmitters for extra safety. The

operator has a transmitter and if something should

happen, a second operator on the ground can take

over the remote control with the other transmitter.

The transmitter controls all movements of the

platform.

Together with GMJ, Åkerströms developed a

configuration tool with which the manufacturer can

manage all system settings and functions required.

The system is designed for easy start up, with its

plug-and-play solution and a removable CIM card.

IN AUSTRALIA

Wide spread

R

emote controls are becoming

increasingly sought after by access

platform operators. As Antonio

Silvestri, Autec Safety Remote Controls

product development manager, explains

such systems have become more flexible to

accommodate machines across the sector, from

self-propelled to large truck mount units.

“The flexible interface and a wide selection

of transmitters and receiver models of the

Autec Dynamic series easily adapt to different

machine control configurations, so there are

few limits,” says Mr Silvestri.

Customers also require control systems

unique to them. Paul Martin, Ikusi product

manager, says, “We customise the systems

according to the needs of the customers and

the particular machine. All this whilst strictly

complying with Annex-F of the EN-280:2013

standard specific to this application, which

regulates safety and obliges us to evolve with

the OEMs.”

Alexander Hemming, head of product

management at HBC-radiomatic agrees,

“There are no changes noticeable regarding

the types of equipment but regarding the

HBC-radiomatic

control in

action.

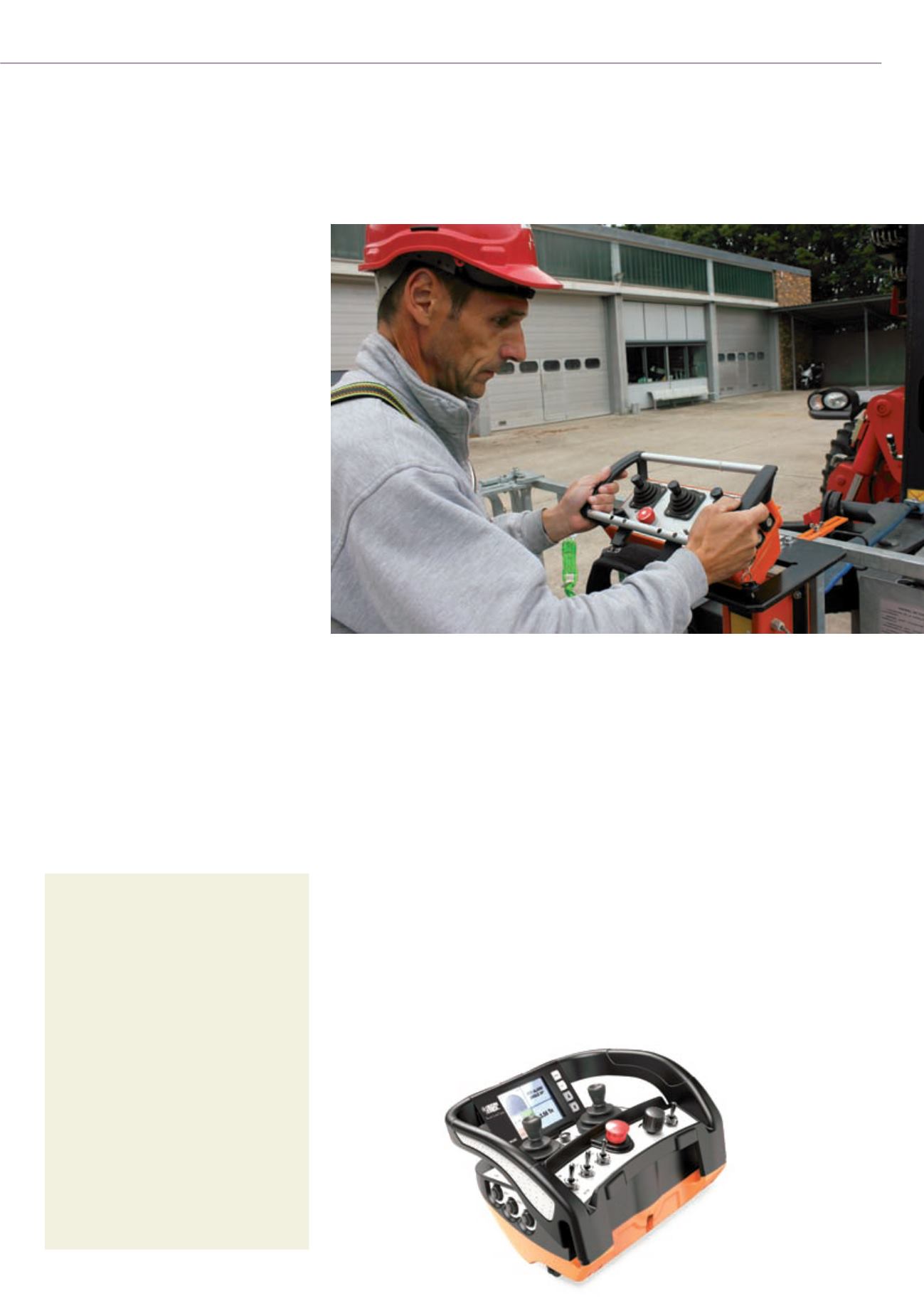

The I-Kontrol from Ikusi.

51

MARCH-APRIL 2014

access

INTERNATIONAL