LIFTING

SITEREPORT

C

onstruction justwrappedup

on432ParkAvenue, ahigh-

rise residential tower in the

heart ofManhattan,NewYork. Topping

out at 1,396 feet, thebuilding isnowNew

YorkCity’s second tallest building (the

third tallest in theU.S.), and for a short

time,will be the tallest residential building

in theworld.After it isovertakenbynew

construction in theMiddleEast, itwill

still remain the tallest in theWestern

Hemisphere.

A26.5-tonPotainMR415 tower crane

wasoneof theproject’smost important

tools. The extremeheights called for an

electric tower cranewithan excellent

climbingpackage, high capacity, and

most importantly, a fast line speed. 432

ParkAvenue is the largest building ever

constructedwithan electric tower crane.

LaGrange,N.Y.-basedRoger&Sons

Concretehandled the liftingworkon the

project. The father-and-son run company

specifically chose theMR415after seeing

itworkonotherhigh-profileprojects.

AsTonyRodrigues explained, the

companywanted tomakeuseof theMR

415’s electricpower andhigh line speeds

that canhit speeds approaching900 feet

perminute.

“Whenyou’repicking loadsoff of aNYC

street and lifting them700 feet ormore

in the air, aquick line speedand sturdy

winch can really cut downon the amount

of time spent on the job,” saidRodrigues.

“Since the constructionwas scheduled

around the crane’s ability to lift, thismeant

the entireprojectwas completed sooner.”

The companybeganusing theMR415

on theproject inSeptemberof 2012.

At that point, thebuildinghad risen to

320 feet,withanother 1,076 feet yet to

be constructed.Afterusing the crane

to remove another crane that hadbeen

usedat thebeginningof the construction,

Roger&SonsConcrete set about lifting

90 foot-long rebarbeam cages and9-ton

rebar column cages thatwere filledwith

components for thebuilding.

Riggedwith98 feet of jib, thepicks

weighedup to24 tons, andmanyof the

loadswereplacedat a72-foot radius

Such great heights

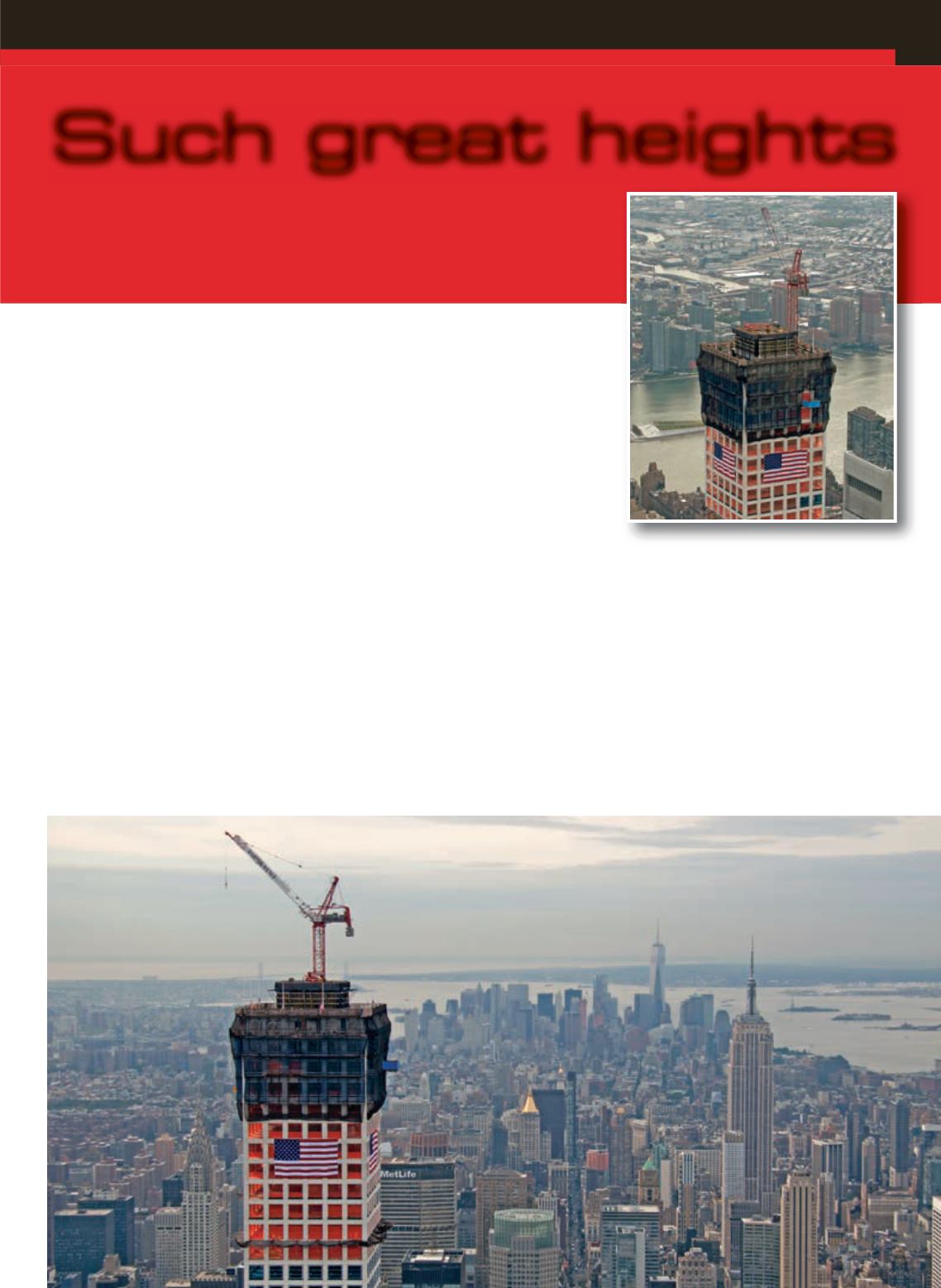

Roger & Sons Concrete recently constructed the

tallest residential skyscraper in theworld using a

PotainMR415 electric tower crane.

Working above the clouds requiredmeticulous focus and

communication between the signal men and crane operators.

37

JANUARY 2015

ACT

(leaving free a remaining27 feet of the

crane’s available radius). Theuseof rebar

cagesmeant the company couldoptimize

eachpick, lifting several items for the

constructionat once, rather than in

separate lifts. Typically, the cranewas set

upwith210 feet of tower, and it climbed

up in thebuildingwithan internal

climbing systemasworkprogressed.

Near the completionof theproject, the

MR415was some1,500 feet above the

street.At that time, line speedbecame

crucial to the successof theproject.At

speeds approaching900 feet perminute,