56

ACT

MAY 2014

SC&RA

JOBSOF THE YEAR

S

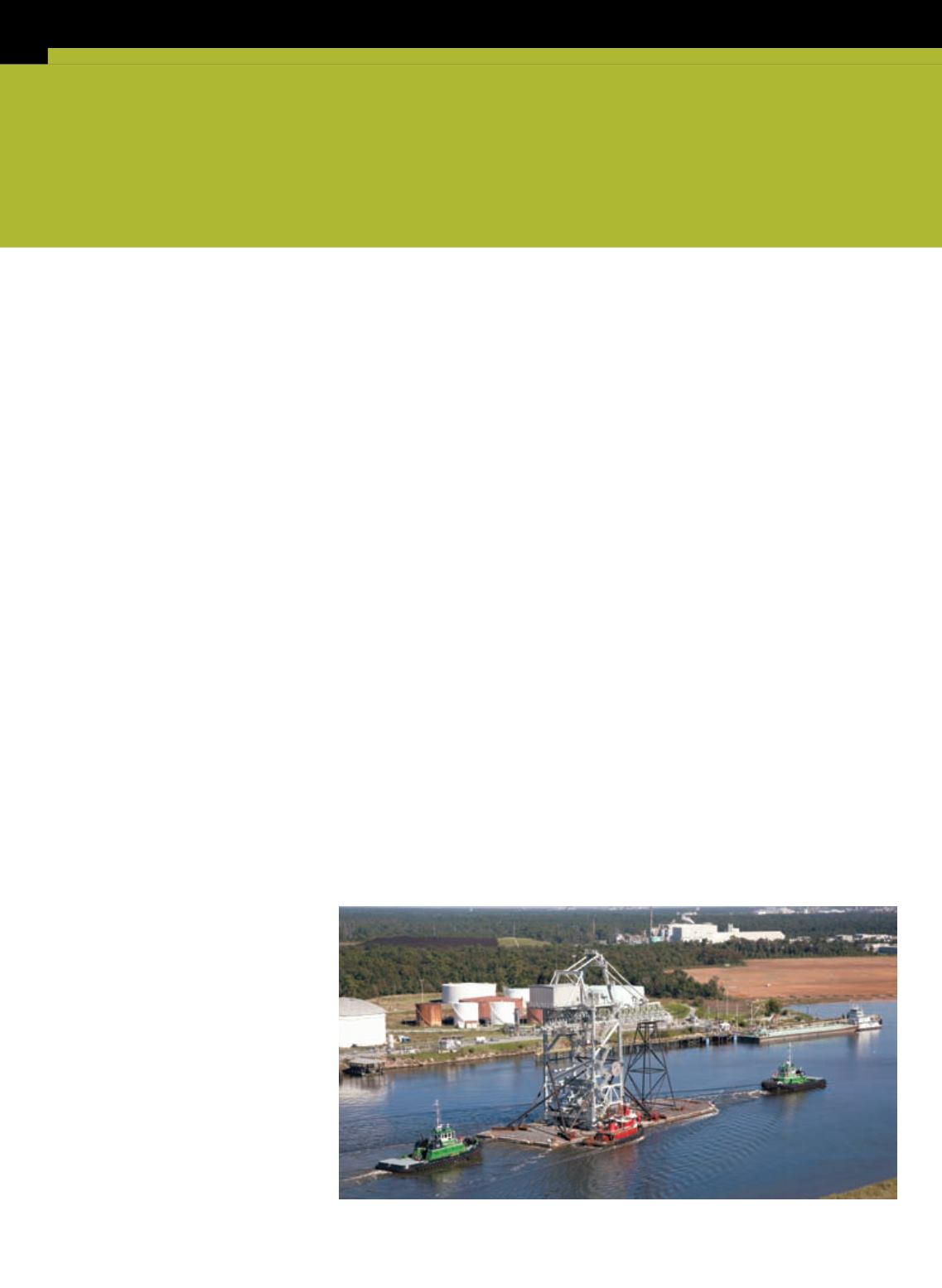

lowly, a gigantic shipunloader

began to take shape at aplant

inNew Iberia, LA.When

completed last year, the 1,000-ton crane

towered181 feet 6 inches high and

stretched211 feet inches longby95 feet 6

incheswide.When fully tested, the crane

performed flawlessly.

But onedaunting task remained–

moving the crane viawaterways to the

Port of LakeCharles, LA, about 97miles

away. BerardTransportation, alsoofNew

Iberia, welcomed the challenge.

TheBerard teampainstakingly loaded

the craneonto adeckbargeusing

steel plating to spread the loadon the

substandard loadout terrain. Flanked

by three tugboats, theunusual load then

proceeded slowly to its final destination,

sometimes passingonly a few feet beneath

highvoltagepower lines.

Further complicating thismoveupon

arrival of the crane at its new, permanent

watersidehomewas theneed to rotate the

crane 90degreeswhileon thebarge to

be inposition to roll off onto an elevated

concretepier. Thismaneuverwas the

equivalent of rolling1,500 tons onto an

elevated concretepilinghighwaybridge.

As the load rolledonto thedock, the team

executed a 90degree left turn at the same

time to lineup the crane’s trucks to the

dock’s rail system.

“Everything from theminiscule

clearances between thepower stations

on thedock, limitedbargewidth and

lackof buoyancy that includedperfect

timingwithhigh tidal conditions added

to the ever changing list of challenges,”

saidBraedonBerard, CEO, Berard

Transportation. “Having toworry about

a vertical center of gravity that towered

75 feet 6 inches greatly increased the

difficultyof this assignment. Another key

was having an experienced teamwith an

outstanding calm,meticulous operator.

The throttle control had tobe veryprecise

andone simplemistakewouldhave led to

a catastrophe.”

The arsenal of equipment deployedby

Berardon this project included52 axle

lines ofGoldhoferESEs, threepower

overseas,” saidDonaldBrinkman, director

of Port Engineering. “Evenmore exciting

is that the shipunloaderwas fabricated

right here inLouisiana.”

ThePort of LakeCharles encompasses

203 squaremiles inLouisiana andowns

andoperates twomarine terminals

and two industrial parks. It is currently

ranked the thirteenthbusiest seaport

district in theU.S. basedon cargo tonnage

according to theU.S. ArmyCorpof

Engineers.

“It tookmanymanhours of engineering,

planning andhardwork to ensure the

jobwent as smoothly as it did,” said

Berard. “Our team came through in fine

style, giving it their all tomake the job

a safe and successful one.We are very

proudof this accomplishment andwe are

extremelyproud tohavebeen chosen for

this prestigious awardof SC&RAMoving

Jobof theYear. This award is a testament

toour team’s dedication tomakingour

companywhat it is andwill continue to

be.”

This project stands tobe awinner for

Berard formany years to come. For the

foreseeable future, the company, which

promotes itself as “TheMegaTransport

Experts since 1945,”will benefit from

thePort’s newoperating efficiencies as it

hauls oversize/overweight loads to and

fromBulkTerminalNo. 1.

■

packs, loading ramps, highvolumewater

pumps, 300-foot by100-foot heavy

transport deckbarge, 40,000pound

winch trucks, barge-mounted65-ton

drumwinches for barge securement and

numerousmats and steel plate for load

spreading.

Adding capacity

Berarddevoted3,893 totalmanhours

to this project and came awaywith zero

injuries. To ensure a safe, successful job,

Berard coordinated its effortswith the

client, anumber of government agencies,

the fabricator, port authorities, water

transportation companies andpower

companies.

The shipunloader crane at Bulk

TerminalNo. 1 immediately enabled

an increase in thePort’s cargo capacity

andhandling efficiencies. The terminal

nowhas twounloaders that canoperate

at the same time. For example, when

discharging cargo from a ship, one crane

will beused toplace thematerial onto

a conveyor belt, while theotherwill be

able to simultaneouslyunload the cargo

directly from ship to truck.

“This projectwas uncommon in that 90

percent of the crane and its components

weremanufactured and constructed in

theUnitedStates becausemost of the

manufacturers for this typeof crane are

MOVING

with Specialized Equipment

Unloader challenge

>58

Berard Transportation

Transporting and installing a giant ship unloader crane required precision planning by

Berard Transportation.