LIFTING

SITE REPORT

47

ACT

from the ground up for reliable operation,

convenient maintenance and easy

transport.

The SL6000 features a mast- mounted

boom hoist winch and boom-mounted

hoist winches to minimize the labor

associated with assembly and disassembly,

Chellino said.

The Kobelco SL6000 also features

advanced safety devices, a wide cab for

enhanced visibility and high structural

strength with reduced weight for

outstanding lifting capabilities.

For the AZZ Galvanizing job, the crane

was equipped with 396,000 pounds of

counterweight, 110,200 pound car-body

counterweight and 217-feet of main boom

at an 83-foot radius.

“We assembled the crane in our own

yard, took down the fence between our

properties, and put down mats to build

a big dance floor for our crane,” said

Chellino. “We waited for a calm day with

no wind or rain before walking the crane

into their yard and setting the tank into

place.”

AZZ Galvanizing Sales Manager

Scott Matalone praised the job after its

completion.

“Chellino Crane should be commended

for being so cooperative and completing

the project smoothly and successfully

without complications,” he said. “We had

used them before on several occasions

for smaller jobs, and we’ve always been

impressed with their friendly, fast

service.”

Because the crane never traveled over

public roadways, no transport permits

were required. Nor was travel time

required for Chellino and his staff.

Chellino Crane completed the project

setting the large kettle tanks in late July

2013.

Rewarding project

The job was rewarding in several ways,

Chellino said. It was completed profitably

at a firm-fixed price while helping a good

neighbor save time and money.

“You don’t get many of those kind of

jobs in your own backyard,” he noted.

Indeed, shortly after Chellino Crane

completed the job for AZZ Galvanizing,

the company disassembled the SL6000

and loaded it up for a transport of more

than 500 miles to the John E. Amos

Power Plant in Winfield, WV.

The three-unit coal-fired power plant

has a nameplate rating of 2,933 MW, and

is the largest utility owned and operated

by Appalachian Power, a subsidiary of

American Electric Power.

After two months of work helping to

bring one of the units back online after an

extended power outage, Chellino and his

colleagues again disassembled the crane

and transported it back to its home in

Joliet in November.

■

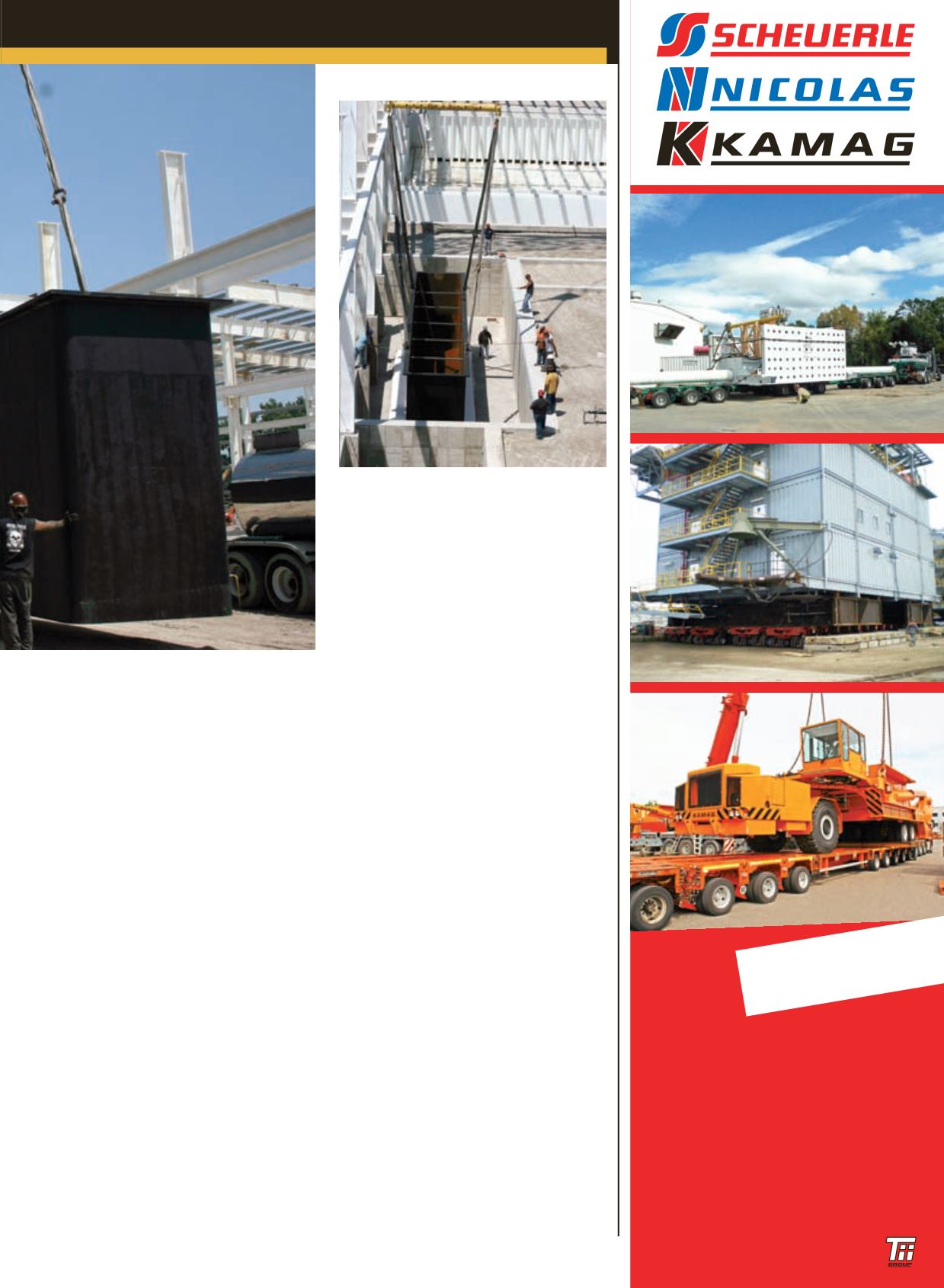

The largest, most significant piece

of work involved the settling and

placement of a new kettle tank

used for galvanizing steel. The

150,000 pound tank measured

50 feet long by 12 feet wide

by 12 feet high.

Using the crawler crane instead of gantries

saved the customer a couple of weeks.

[

Vision becomes reality

with transport vehicles of theTII Group

Achieve your vision with trans-

port solutions from SCHEUERLE,

NICOLAS and KAMAG. We offer our

LOPX IPX UP æOE UIF PQUJNBM TPMV-

tions for your transportation requi-

rements.

Visit us at the

ConExpo in Las Vegas

Silver Lot 1,

Booth N3905