45

TRANSPORT

SITE REPORT

DECEMBER 2013

ACT

For this bridge, the four main pieces were

put in place in 48 hours, and complete

bridge replacement was done in two

weeks. It’s way less grief for public users.”

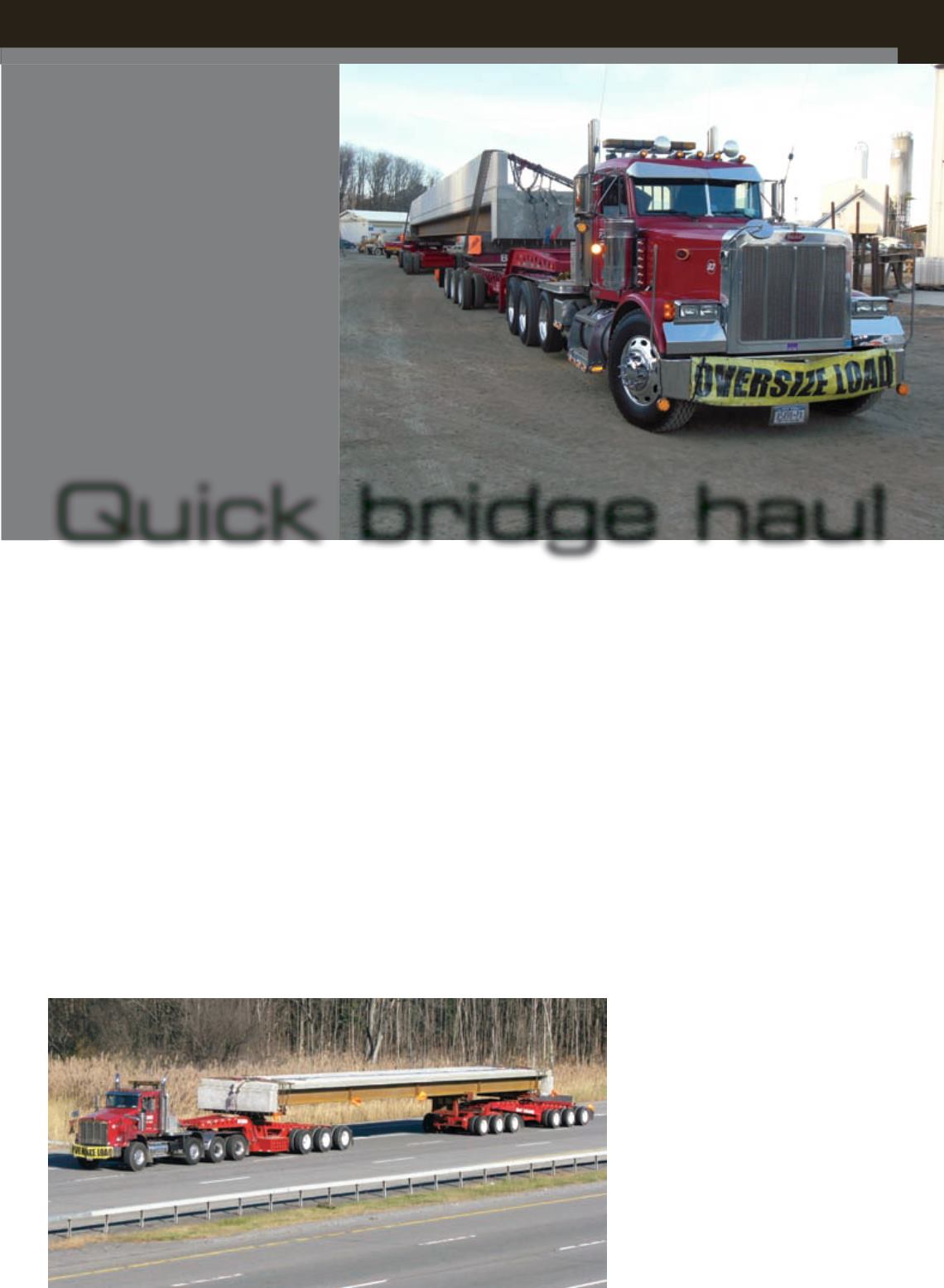

Bay Crane’s crew hauled out two

sections at a time, using a six-axle

steerable dolly, a four-axle tractor and a

six-axle jeep, he said.

“We had both rigs set up the same

way,” he said. “We hauled the first two

on a Wednesday and then went back and

delivered the second two sections on a

Friday.”

Leading bridge fabricator

The route was 223 miles from the Fort

Miller Company in Easton, NY to the

bridge site at Interstate 81 over Preble

Road in Cortland.

“Fort Miller is one of the leading type of

fabricators who are addressing this type of

need for rapid bridge replacement,”

he said.

S

cores of bridges have been

deemed insufficient in the

United States, which means

bridge replacement is big business. Bay

Crane has been involved in several bridge

replacement projects, most recently in

Cortland, NY.

The scope of the job was to transport

four sections, two interior spans and two

exterior spans with walls. The exterior

sections weighed 100 tons each and the

interior sections weighed 90 tons each.

Falling in the category of Rapid Bridge

Replacement, the four sections, put into

place, means a complete bridge, according

to Gregg Barry, vice president for Bay

Crane, based in Long Island City, NY.

“It used to be that a bridge would be

closed down and traffic diverted until

a new one could be built, which could

be a long time,” he said. “But today, you

can put up a 42-foot-wide, 90-foot-long

bridge and do it completely in two weeks.

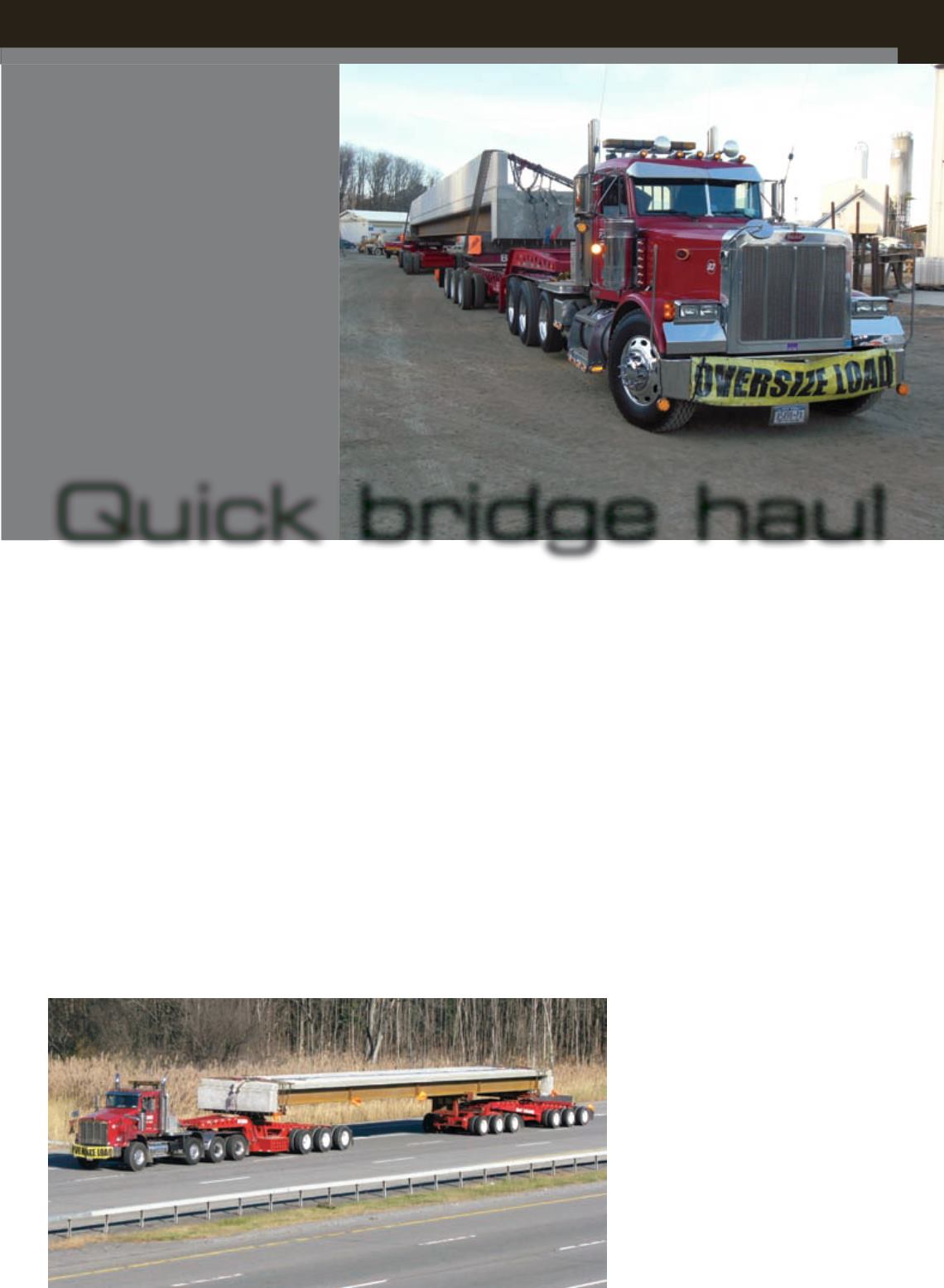

Bay Crane hauled four

bridge sections for a

Rapid Bridge Replacement

project in Cortland, NY.

Bay Crane’s crew hauled out two sections

at a time, using a six-axle steerable dolly,

a four-axle tractor and a six-axle jeep.

Quick bridge haul

The interior sections were 12-foot,

6-inches in width and 87-feet-long while

the exterior sections were 87-feet-long but

10-feet, 6 inches in width.

Two escorts, a state police escort and a

service truck were a part of the convoy,

which was allowed to travel during

normal business hours.

The sections were loaded onto the

trailer system at the Fort Miller plant by

two cranes owned and operated by the

company.

At the bridge site a 500-ton AC Terex

Demag 550 unloaded and placed the

bridge sections.

“It was a great project,” said Barry.

“When you start a job like this, your

adrenalin is up. It’s like getting ready for a

big football game. The demands are tough

but once you are done there’s a feeling of

satisfaction for what was accomplished.

Within a week of the job being

completed Bay Crane received a letter

from the client thanking them for their

work.

“Your guys busted their [butts] while

here and once on the road. They are

good men. Hardworking, dedicated,

well mannered. They are welcome here

any time. You can be assured that they

represent Bay Crane very well, both at our

plant and on the jobsite.”

■

Two escorts, a state police escort and a

service truck were a part of the convoy,

which was allowed to travel during normal

business hours.