international

construction

april 2015

EARTHMOVING

46

New technologies

machinewhichoffers an integrated systemof intelligent controls

that useGPS, which is a bigmove on from them being entirely

separate systems. “Our3D-MC really is agame-changer in terms

of its ability to savemoney for construction companies.

“Itworks throughusing the 3Dmodelling fromdesigners used

by contractors to create automatic computer-based control of

howmachines are operating their blades and other attachments.

So, providing the original modelling specifications are supplied

correctly, the scope for human error ismuch reduced.”

Monitoring and control

Mr Hermanski added that one of the company’s latest areas of

focus has been its Sitelink system, whichworks in tandemwith

GPS through computer-basedmonitoring and control

of construction sites to improve the efficiency of

projects.

In his opinion, the timely and effective

delivery of construction projects was of

critical importance, and the use of tablet-

based apps and smart phones in addition

to GPS-based technology was having a

significant impact.

He added, “In construction, it is often

the case that around 20% that is spent

on a project amounts to waste. We

want to be able to control that using

GPS and 3D modelling software to

bring this down to near zero. It’s this

kind of waste that is unnecessary.

“At present, somewhere between

8 and 10% of companies have

adopted GPS-based systems

within construction machines

– in surveying it is now pretty

much 100%.”

He continued, “The challenge

now is to build relationships with

machine manufacturers so that the level

o f

growth that we are seeing continues. It has been a

very good year for us, with links such as those we

have developed with Komatsu working well – it is

things like this that people are really talking about

within the industry.”

The company’s link with Komatsu has involved installing

Komatsu excavators anddozerswith itsmachine control systems

to improve their productivity.

Valentin Fuchs, programmemanager for 3D sensors and field

machine control at Leica Geosystems, said that in addition

to providing aftermarket products, there had been a growing

demand for developing factory-integrated complete solutions

usingGPS, something it does withCase.

He said, “There’s a lot of systems integration for GPS use

withinmachines that we are able to provide some very elegant

solutions for.This has meant that a lot of operations that were

previouslydoneby radio communication arenowdonewithon-

boarddisplays withinmachines.”

Oneof its latestproducts, the IconGPS80, hasbeendeveloped

for a range ofmachine controls applications.

Mr Fuchs added, “The focus of this receiver generation

was on dynamic performance in typical and difficult GNSS

environments.We increased equipmentuptime andproductivity

because it’s extremely important to our customers on site.”

Machine design principles

One of the first steps in developing any new construction

product is indeveloping initial concept designs.

Companies such as Liugong have acknowledged that

developing machines that not only efficient, but are visually

appealing as well, is of increasing importance.

As director of the company’s industrial design division, Gary

Major, said there had been a number of challenges the business

had faced in terms of design.This includes developing theoverall

Liugong brand through creating distinctive designs.

Mr Major said, “Today’s end-users are far more design savvy

than theirpredecessors, soaesthetics is ahugely-important factor.

“Engine emissions have changed components such as

powertrains and the particulate filter assembly, growing their

size enormously. Because of that, engine enclosures are now

huge, which creates challenges in meeting machine sightline

requirements, which in turn impacts the overall

aesthetics ofmachines.”

However, he added that a move towards

composite materials has allowed designers

greater freedom to explore bolder

possibilities.

From improvements inmachinecontrol,

through to advancements in the physical

design of earthmoving equipment,

the development of machine is

clearly continuing to evolve and

make the most of key technology

breakthroughs.

iC

Hyundai will

have a presence

at Intermat,

featuring its

latest range

of excavators,

including the

HX300L.

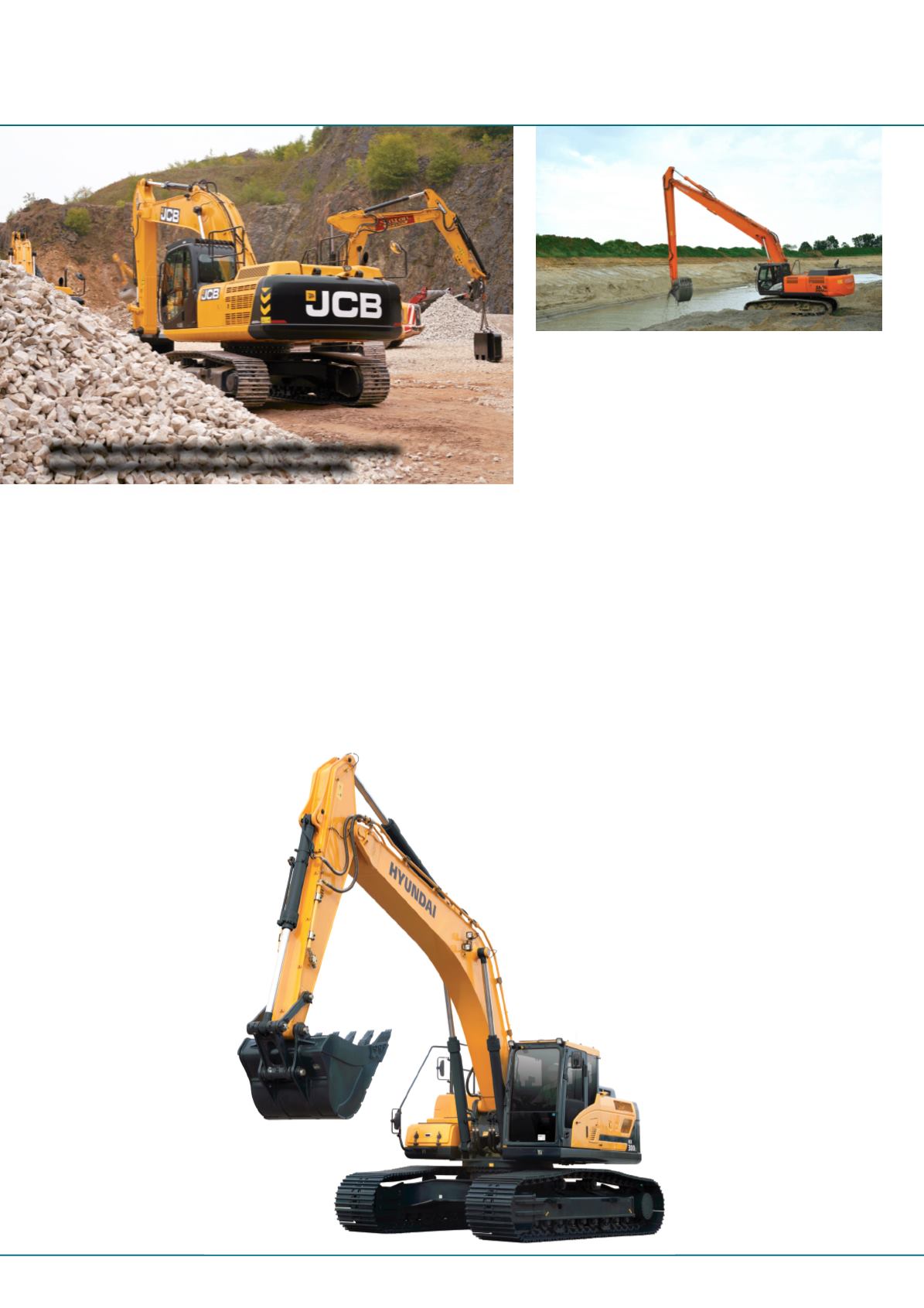

JCB has expanded its JS rangewith its JS300, which promises

greater power and performance over previousmodels.

Hitachi will have a presence at Intermat thismonthwith its

range including the ZX350LC-5 excavator, which has a

202 kW engine and EU Stage IIIB/Tier 4 interim engine.