EQUIPMENT

58

international

construction

june 2014

Caterpillar

As a productionmachine, the 950

H canbe fittedwith a slightly larger

maximumbucket size than the 950

GC, and some of its rear structures

aremore robust.However, the 950

GChas a bitmore dump clearance

tohelpwith truck loading.The

front end is a traditional Z-bar

linkage, andwhileCaterpillar

says themachine canbe used for

productionwork, it is intended

more for lighter applications.

Power comes from a 168kW

CatC7.1 engine, whichmeets

Stage IIIA/Tier 3 emission laws

and the company says this has a

fuel injection systemdesigned to

copewith the poorer quality fuels

that are often found in emerging

countries.There is anon-demand

fan and the robust cooling system

means the loader canbe used in

temperatures up to50°C.

The simple technology theme is

apparent in the powertrain, which

provides four forward and three

reverse speeds via aCaterpillar-built

powershift transmission.The axles

feature in-boardplanetary drives

andwet disc brakes, and limited-

slipdifferentials are available as an

option.

Workhorse excavator

Anothermachine thatCaterpillar

has rethought is the 20 tonne class

320D2 tracked excavator.This is

by far themost popular excavator

sizeworldwide, particularly in

emergingmarkets, andCaterpillar’s

discussionswith customers led

it to the conclusion that greater

simplicitywouldbe theway to

improve it.

One of the key aspects of this

was to go from an electronic to

mechanical engine tohelpwith

fuel quality issues. AlexFavero,

Caterpillar’s hydraulic excavator

product application specialist for

EAME said, “For theMiddleEast

andAfrica, the quality of fuel is

very low. In electronic engines,

the pressures is huge, 2,000bar or

so in the injectors, so if you get a

blockage youhave a huge problem.

In amechanical system, the pressure

is only around200bar.”

This greater tolerance topoor

fuel shouldnot onlymean greater

reliability, but it has also allowed

Caterpillar to generate potential

savings in consumables.The

previous 320Dhad four fuel filters,

with a recommended replacement

interval of 250hours.Now there

are just two, and the interval has

been stretchedout to500hours, so

this aspect of themachine’s running

cost is a quarter of what itwas.

Despite the change to a less

sophisticated engine, Caterpillar

says there is about a 3% fuel

efficiency improvement on this

machine over the previousmodel,

compared to the last. Another

change is the in-cabmonitor and

newEcomode.Themachine always

starts up inEcomode as a default

(althoughowners can change this

setting).The operator can switch

toPowermode if required, but

Caterpillar says running inEcowill

save 10% to15% in fuel costs.

More to come

These twomachines are just part

of a newportfolioof equipment

Caterpillar is launching in the

MiddleEast andAfrica this year.

The 320D2 is just one of nine

tracked excavators thatwill be

released to cover the 20 to90 tonne

operatingweight classes. It is a

wide spreadofmachines, but asMr

Lavassani said, “Excavators are 70%

of themarket in the region.”

In addition, there are twowheeled

excavators to come alongwith a

grader and scraper.

iC

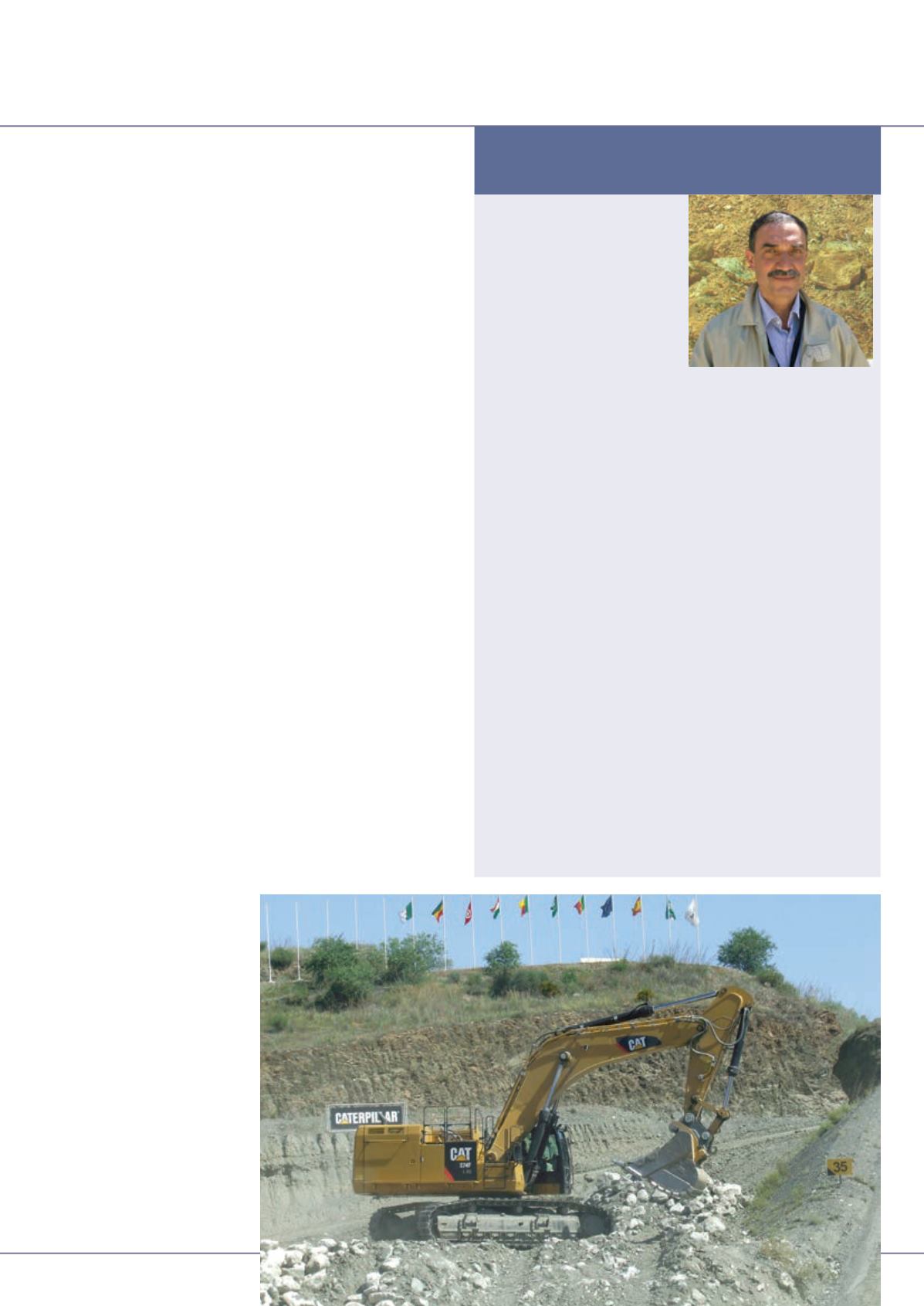

The 75 tonne class 374F is one

of nine tracked excavators

Caterpillar will launch in Africa

and theMiddle East this year.

Rental expansions

Pioneering Tunisian dealer plans for growth

P

arenin, Caterpillar’sdealer

inTunisia, hasbeen

formally rentingmachines

for 15 years, andexpects its

fleet tobreak the100machine-

markwithin thenext two years.

Thismaynot sound likemany

byEuropean, Japaneseor US

standards, but it isbelieved tobe

Tunisia’sbiggest rental fleet.

Andkeydifference in theway

thecompanyoperates itsCat Rental Store franchisecompared toother

partsof theworld is that all themachines it rentsgooutwithanoperator

trainedunder aCat-certifiedprogramme. According toMustapha

Farjallah (pcitured), Parenin’smanager for rental andusedequipment,

thishelps ensuremachinesareused safely,maintainedandnot abused.

It alsohelps toensurepayment andprevent theft.

“Wewill continuewithoperators for a few yearsat least. Nowwehave

VisionLink (Cat’s telematics system),wemight beable tochange things

anduse that to follow themachineand trackmaintenance. But for now

wehave70machinesand70operators,” saidMr Farjallah.

Andhe said thefleet is set togrow. “Wehave lotsof newbusiness

opportunities. Therearehighwaysbeingbuilt aswell asagaspipeline

andweneed tobe ready for that. Iwill reach100machineswithin two

years.Wehavea lot of businessbecauseTunisia isapermanent job site

thesedays,” saidMr Farjallah.

But as inany embryonic rentalmarket, oneof thebigchallenges is to

overcome theownershipmentalityamongcontractors. “Theculture in

Tunisia is toownmachines, so it hasbeenhardwork tochange that.We

have focussedon foreigncompaniesbecause theyprefer to rent,”he

added

AndMr Farjallah saidall thecompletionParenin faced in the rental

sectorwasof amore ‘informal’ kind. “Weare theonly structured rental

company (inTunisia). Thecompetitionwehaveare ‘taxi stand’ people,

whobuyamachine likeabackhoe loader and rent their services.”

However, he said thatmore serious competitionwason thehorizon.

“Weareapioneer for rental inTunisia. I think therewill beamore

structuredcompetition in the future. I believeVolvo is lookingandLoxam

hasmadea studyof themarket,”heconcluded.