international

construction

october 2013

FALSEWORK & FORMWORK

26

Special solutions

A key challenge for falsework and

formwork suppliers is to help contractors

execute complex projects on a tight

budget, which often means providing a

bespoke solution using standard, modular

components.

Chris Sleight

reports.

A

rchitects may be fond of coming up with extravagant

and elaborate designs for everything from bridges to

skyscrapers, but the challenge for contractors is to execute

these complex schemes on time and on budget. It is an area where

suppliers can not only help with technical advice and specialist

design services, but also suggest ways to make the construction

process more efficient.

When it comes to falsework and formwork, this often means

providing solutions that allow complex and ever-changing shapes

to be constructed using standard components that are easy to

handle and modify on site.

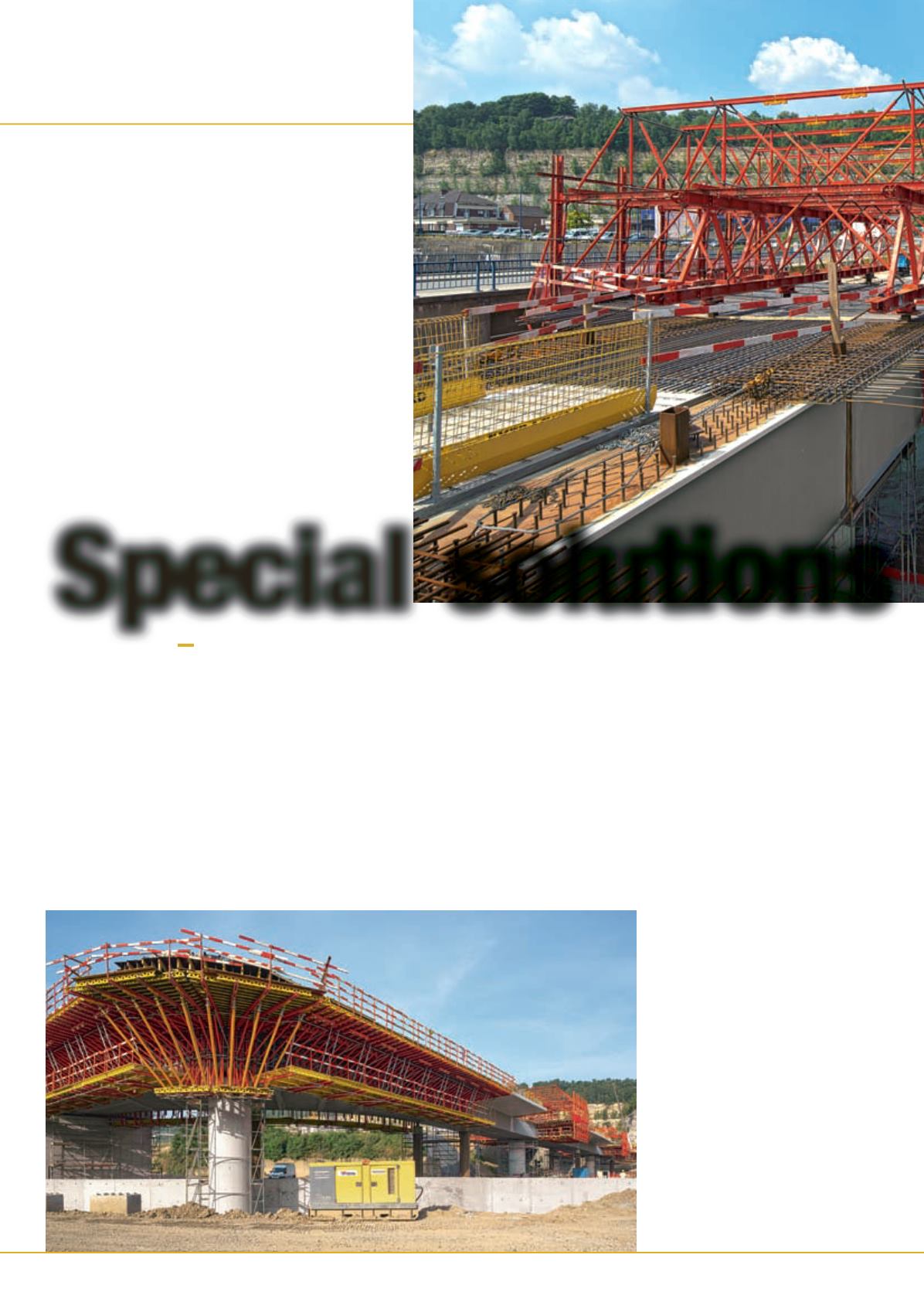

Peri for example has seen its Variokit modular system being

used for construction of a steel composite bridge over the

extended Lanaye lock facility in Belgium, on the border with the

Netherlands. Although based on standard rentable components,

the formwork system has a complex function, acting as both a

movable carriage and a cantilever bracket.

The locks link the Albert Canal with Juliana Canal, a side

channel from the River Meuse. Construction of additional lock

chambers will quadruple capacity, and as part of this project, a

new 200 m long road bridge, with a 136 m main span, is being

built across the shipping channel.

The S-shaped, 15 m wide bridge has cantilever lengths of 4.5 m,

and these are being built using two Variokit composite formwork

carriages, while radially-arranged Variokit cantilever brackets are

being used for two 30 m long tightly curved approach structures.

The steel composite design involves first placing box-section

steel beams, which support the slabs that are formed using the

two Variokit carriages. The project involves casting the slab in 13

segments, from 8 m to 12 m long to a tight schedule, and the

formwork carriages were delivered pre-

assembled to reduce the time required on

site.

They move on heavy-duty rollers

which are mounted on supports on the

steel structure with 4 m spacings. Their

design features a longitudinal truss made

out of standard main beams. The lateral

units were designed to be adapted to

the specified bridge section, and the

system also helped with on-site safety.

For example, the tie suspensions of the

cantilever formwork were handled entirely

from above.

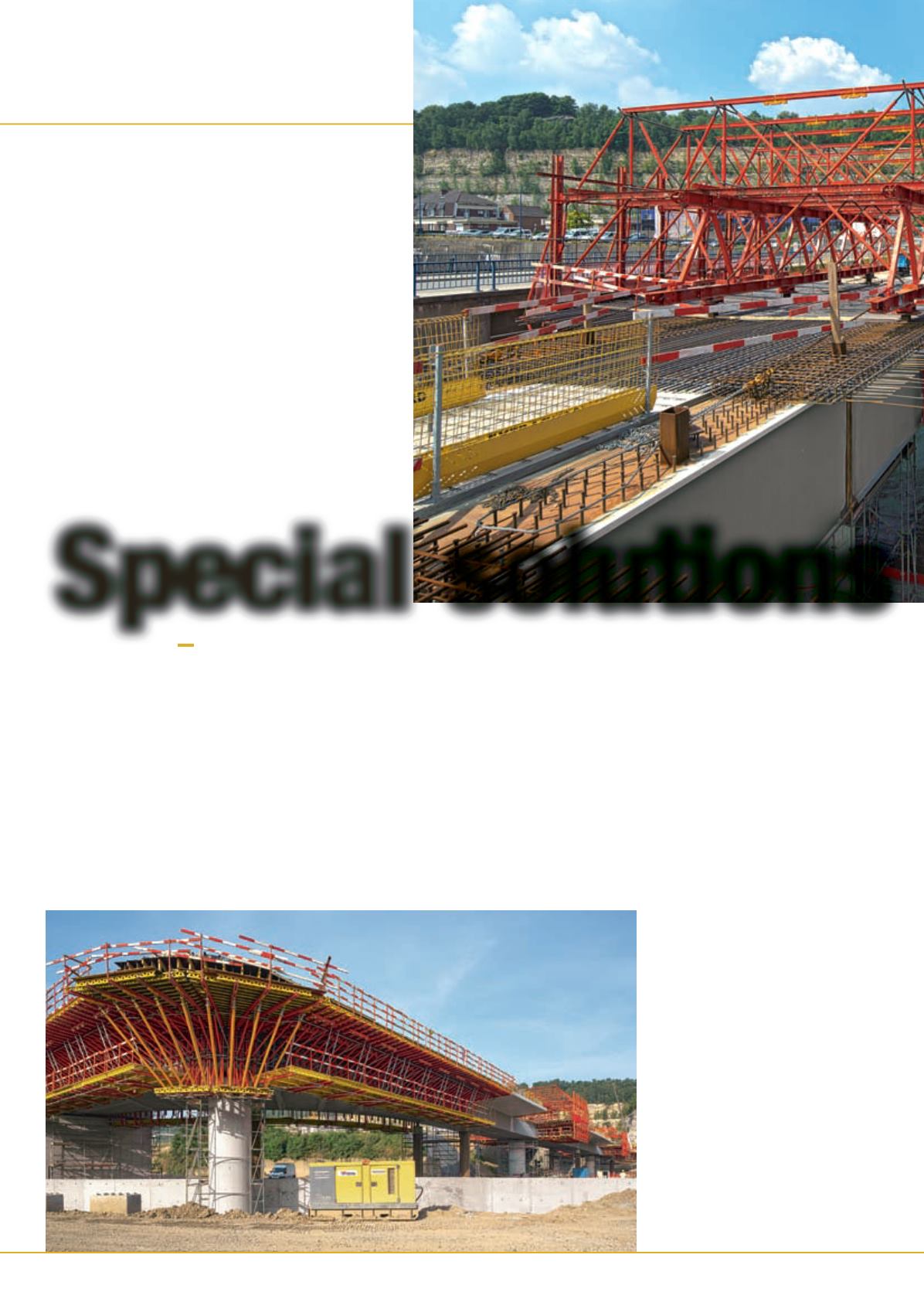

On both banks of the river, the bridge

alignment features two 90° bends –

complete with extremely tight axis radii of

almost 30 m respectively, and these were

built using Variokit cantilever bracket

units mounted on steel beams.

Special solutions

Despite the tight geometry,

formwork for the two 90°

bends on the approach to the

new Lanaye lock road bridge

were built using standard

Peri components.