INTERNATIONAL

ANDSPECIALIZED TRANSPORT

■

APRIL 2015

WORLDNEWS

11

Barloworld launches

SAcranedivision

A cranedivisionhas been

added toBarloworld

Transport, extending the

company’s range of transport,

lifting andhandling services

inSouthAfrica. Barloworld

Transport is part of Barloworld

LogisticsGroup.

BarloworldCraneswill be

runbyReboneMotsatsiwho

has been appointedmanaging

director and IanGerrard

will be operations director.

Motsatsi is an industrial

engineering graduatewith

logistics industry experience.

At BarloworldLogistics he

was business development

head:mining& construction.

Gerrardhasmore than40

years of experience and is an

expert in crane, rigging, heavy

lifting andheavy transport

projects, Barloworld said.

The fleet includes seven

Liebherr all terrain cranes

between40 and200 tonnes

capacity and sixTadano truck

mounted cranes from34 to

60 tonnes. The cranedepot

will be in Isando, Kempton

Park. Additional services

offered include rigging

engineering, CAD job

planning, integratedproject

solutions, site inspections,

risk assessments and

projectmanagement.

Commentingon the

newdivision, SteveFord,

BarloworldLogistics chief

executive, said, “Barloworld

Cranes represents another step

inour journeyof investing in

nicheproducts and services

enablingus tooffer our clients

moreholistic supply chain

solutions. It is anatural fit

toour business, specifically

for clients needing tomove

abnormal cargoor engaging in

specializedprojects.”

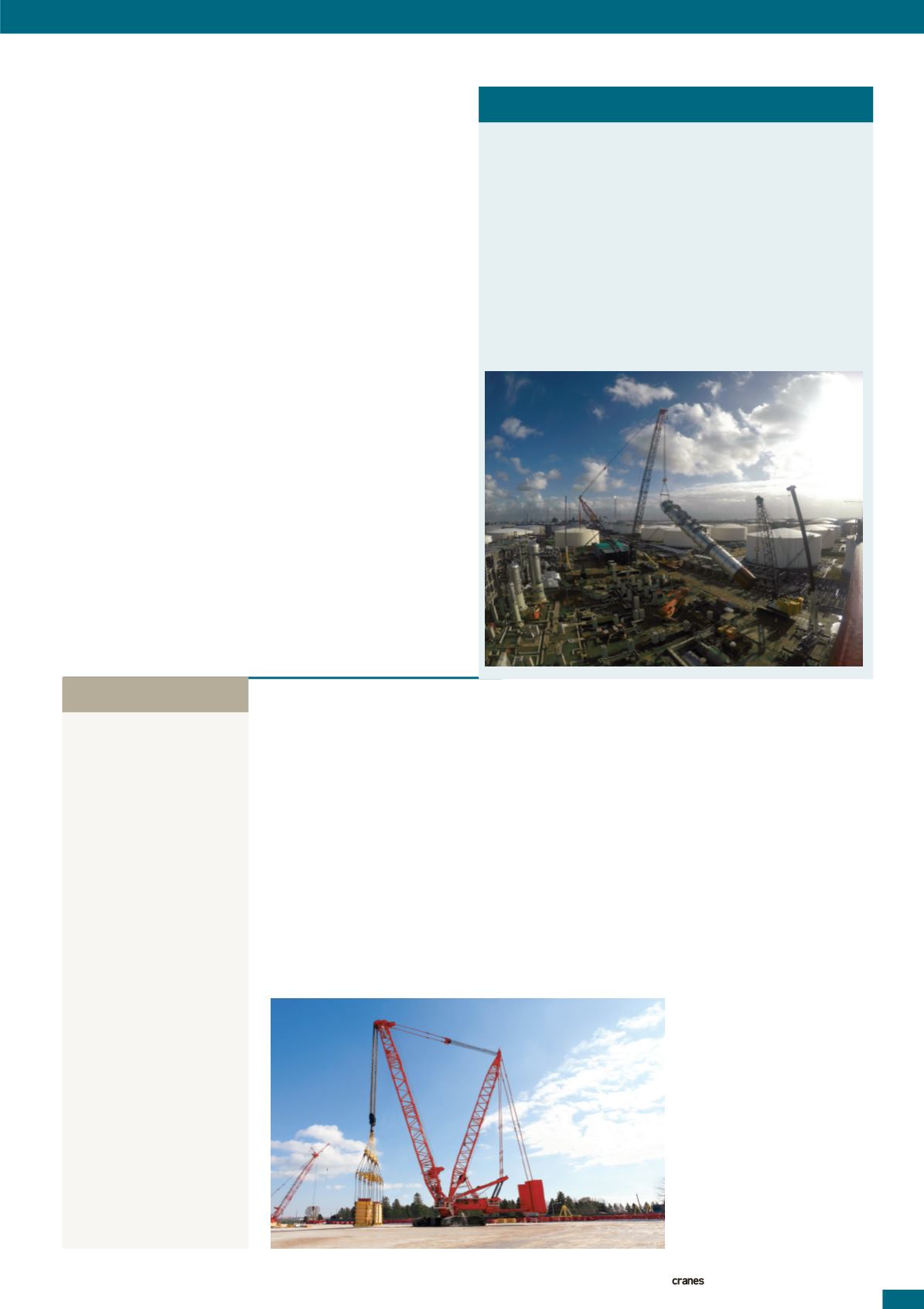

Lifting service provider AertssenKranen and international heavy lift

and specialized transport specialist ALEhave finished installing the

main fractionators at theOptara project inAntwerp, Belgium.

TheOptara project forms part of a €1 billion (US$ 1.1 billion)

investment from Total at the refining and petrochemical complex in

Antwerp. Work at the sitewill include the construction of a newunit

and the conversion of an existingunit, a spokesperson said.

Themain fractionatorsweighed250 tonnes andmeasured 57

metres long and had a diameter of 10m. It wasmoved to position

using 32 axle lines of self propelledmodular transporter (SPMT).

Once inposition, a 650 tonne capacity TerexSuperlift 3800 crawler

cranewas used to lift and install the fractionators. A280 tonneHitachi

SCX2800-2 crawler cranewas used as a tailing crane.

MILESTONEREACHED INOPTARAPROJECT

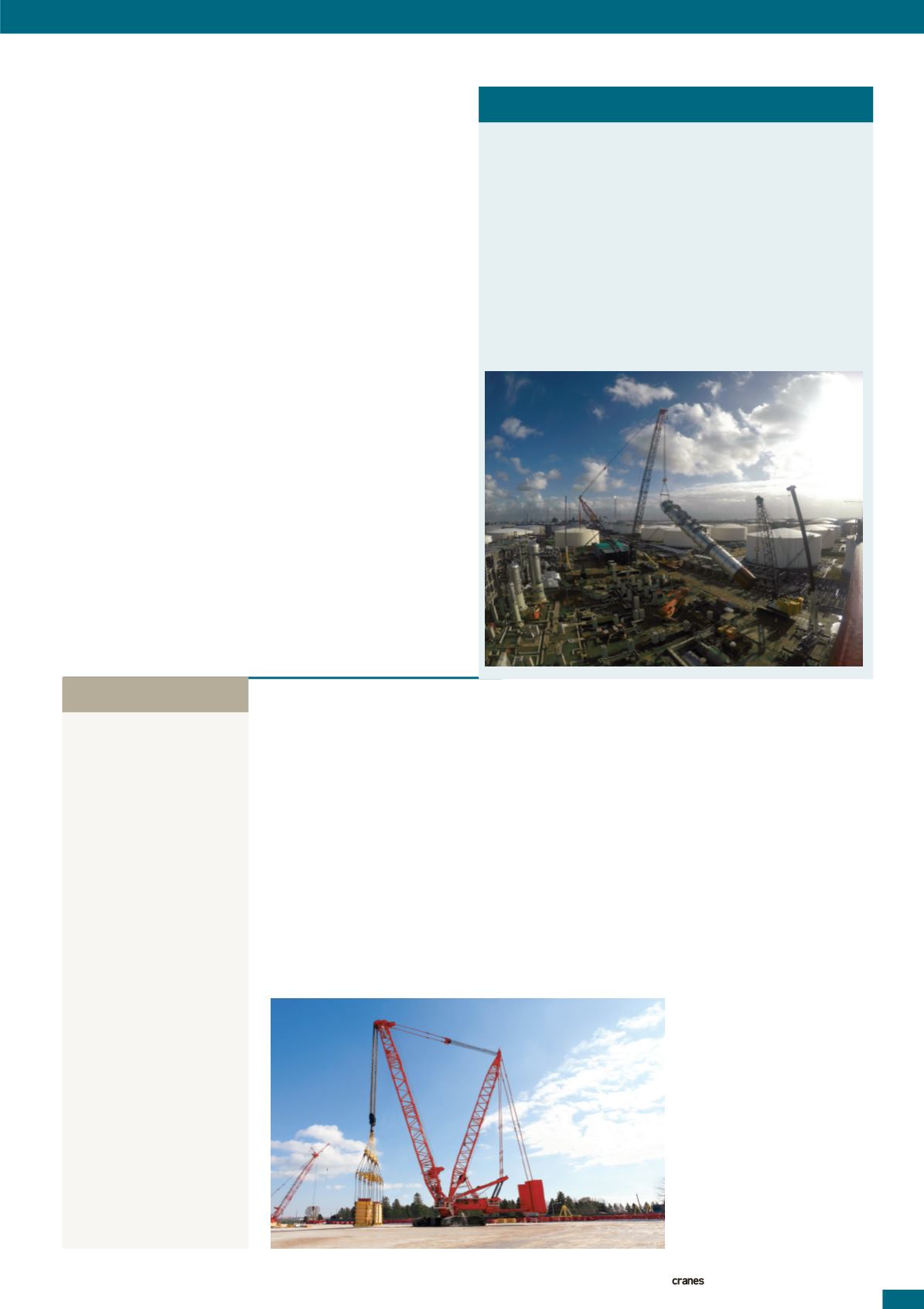

ManitowoccompletesMLC650

crawlercraneVPC-Max testing

Manitowochas completed

load testingof itsManitowoc

MLC650 lattice boom crawler

cranewith the variable

position counterweight (VPC)

Max attachment.

TheVPC-Max attachment

raises the capacityof the

MLC650 to700 tonnes.

It includes additional

counterweight and a beam

that automatically extends

the counterweight basedon

the load.

In addition, theVPC-Max

attachment requires fewer

components and assembly

steps, themanufacturer said.

For the load test, the crane

was positioned to apply the

maximum stresses through

the structure, including the

For theVPC-Max

load test, the crane

waspositioned to

apply themaximum

stresses through

the structure

boompositionedover the

corner of the crawler crane.

DustinSoerens,Manitowoc

marketingmanager for lattice

boom cranes, explained, “We

attachedhundreds of strain

gauges to theMLC650 and

picked anumber of loads

in the test yard to test its

capacitywith theVPC-Max

attachment.

“The testingwent very

wellwithno surprises.No

changes areneededon

the crane, as it performed

superbly.We’rewell on

ourway to releasing this

innovative crane to the

globalmarket. The successful

testingwas agreatmoment

for everyone atManitowoc,”

Soerens commented. “We’re

workingveryhard to release

a crane thatwill define the

next generationof lifting

equipment.”

HIGHLIGHTS

■

The Lifting Equipment

Engineers Association (LEEA)

has released a statement

for UK employers regarding

their obligation to undertake

periodic thorough examination

of all lifting equipment.

LiftingOperations and Lifting

Equipment Regulations

(LOLER), companies are

required to conduct thorough

and frequent examinations

of lifting equipment. The

advice comes after LEEA

wasmade aware that some

users of lifting equipment

are being incorrectly

advised to extend all the

intervals between thorough

examinations to 12months.

Thorough examinations are

usually conducted by external

companies and LEEA is keen

to stress that responsibility

for compliancewith LOLER

lieswith the owner of the

equipment, not suppliers

of examination and

inspection services.