46

INTERNATIONAL AND SPECIALIZED TRANSPORT

■

AUGUST 2013

OPERATOR TRAINING

Although operator training is moving forwards, both in terms of technology and safety, legislative

requirements and training standards around the world sometimes don’t keep up. Harold McBride

explains, “There are many developing countries that are experiencing construction booms

where occupational health and safety are all but non-existent. Companies and legislative bodies

recognise that training is needed to reduce equipment downtime and damage, but the safety

standards that come with the training are seen as an unreasonable cost.”

To help overcome these situations, companies, including crane manufacturers, are providing

training programmes to help keep operator training around the world up to date. Manitowoc

Crane Care, for example, offers operator training around the world, and has centres in Italy and

France. In the UK, Ireland and Trinidad and Tobago, the UK’s accredited lorry loader training

scheme (ALLMI) provides training programmes that cover all UK requirements and legislative

issues specific to those countries.

CM Labs also incorporates certification tests. “Within their training exercises operators

can practice standard tests such as the National Commission for the Certification of Operators

[NCCCO] tests using different types and sizes of cranes,” explains Loze. “Similarly, Vortex

Simulators can be used to help operators train and prepare for NCCA-accredited Crane Institute

Certification (CIC) exams.”

MEETING STANDARDS

surround sound speakers.

“Additionally, a motion base ensures that

the driver experiences realistic movement,”

Hans-Jörg Schwärzler, from Liebher-Werk

Nenzing, adds, “There is also a head tracker

which uses head movement to calculate the

view accordingly.”

Programmes

The improvement in simulator technology

has encouraged most, if not all, training

providers to incorporate simulators into

their training programmes. The OETIO,

for example, use a range of simulators in

conjunction with its training programmes,

from mobile crane simulators to simulators

for wind turbine erection.

Crane manufacturer Manitowoc’s

training division, Manitowoc Crane Care,

also includes real-life cabs with built-in

simulators inside the training centre in

Shady Grove, USA. Alexander says, “The

world of crane simulators has advanced

dramatically in recent years. It is a complete

contrast with the simulators that were

around as recently as a few years ago and

as technology develops, I think we will

see more simulators used for training and

fewer live cranes.”

“The rapid development of simulation

indicates that it will one day be possible

to substitute actual crane training with

simulator training,” Schwärzler concludes.

■

A trainee taking part in a truck crane

training course at the OETIO

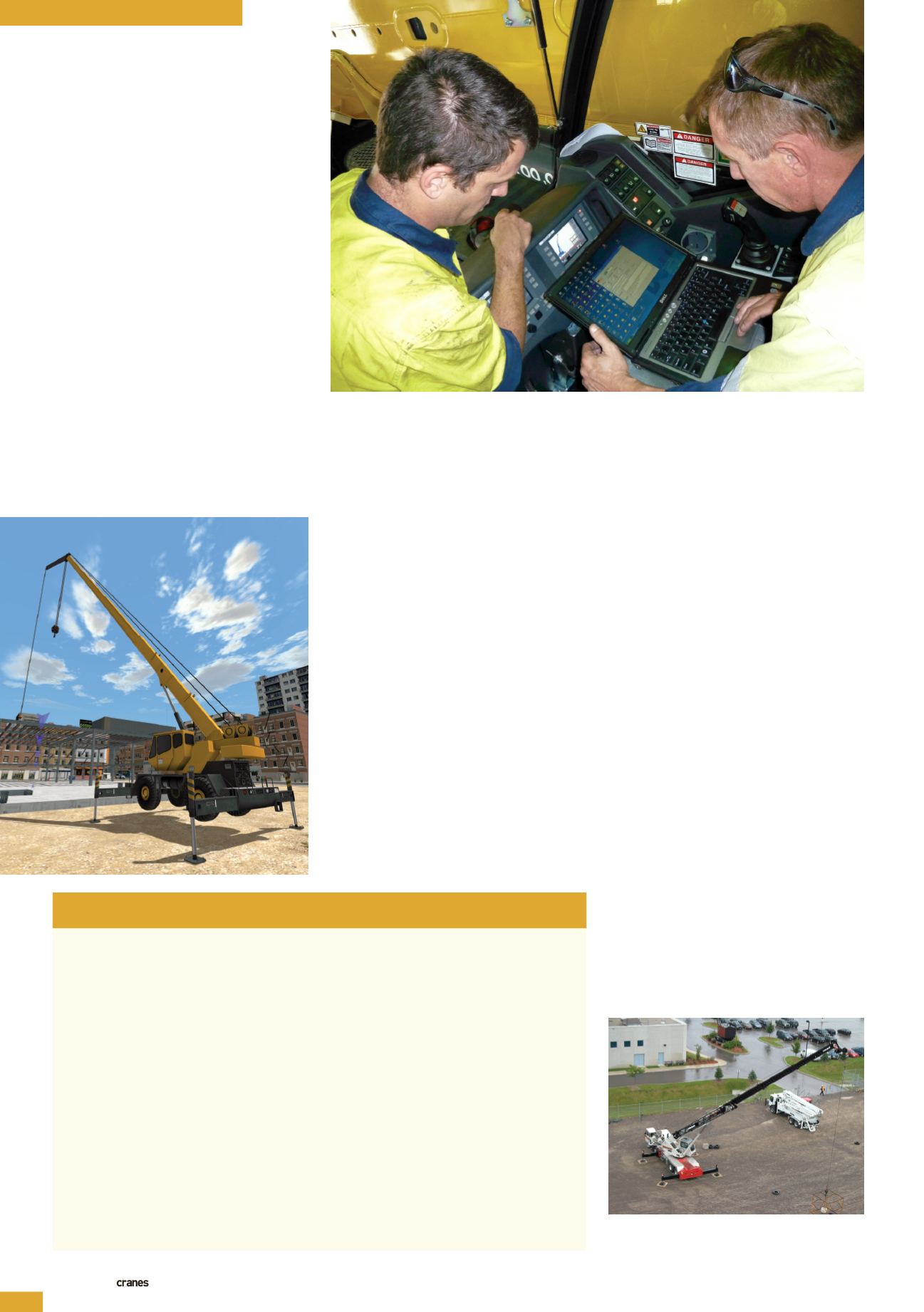

Hands-on

training in one

of Manitowoc’s

facilities in

Australia

who is trained and certified on one of

our older Manitowoc 4100 crawler cranes

might be an excellent operator, but it does

not mean they can just step into an 18000

and know how it all works.”

Simulation developments

Crane simulators have developed over

the years and now include a range of

environments. CM Labs, which works

in partnership with the OETIO and the

International Union of Operating Engineers

(IUOE), offer simulators for tower cranes

and mobile cranes to knuckle boom

offshore cranes and straddle carriers. All

options come with full simulation of crane

dynamics, cable systems, load dynamics, lift

operations, and ship or platform motion.

“Of course, simulation is always

second-best to the real equipment so we

do our best to make the experience as

realistic as possible,” Loze, says, “This

includes having real seats and controls,

authentic worksites, sounds and a head-

tracking system for precise points of

view. Additionally, a 3-degree-of-freedom

motion platform replicates the motion and

vibration experienced by the operator while

travelling and lifting.”

Also featuring OEM seats and

controls and motion based technology,

are simulators from TenStar. “It is very

important to us that the student is fully

immersed in the training experience,”

Hogg explains. “Our simulators have third

party lasers, Global Navigation Satellite

System (GNSS) machine control systems

and bucket tilt rotators. There are dedicated

exercises that focus on the use of these

attachments.” Tenstar simulators include

tower crane, truck mounted crane and

timber truck crane simulators.

Crane manufacturer Liebherr also offers

training simulators. Liebherr simulators

(LiSIM) include ship-to-shore gantry

cranes, rubber tyre gantry cranes, mobile

harbour cranes and offshore cranes. The

simulators have full high definition (HD)

flat screen monitors and high quality

Realistic detail improves the

crane simulator experience