69

november 2014

international

construction

EQUIPMENT

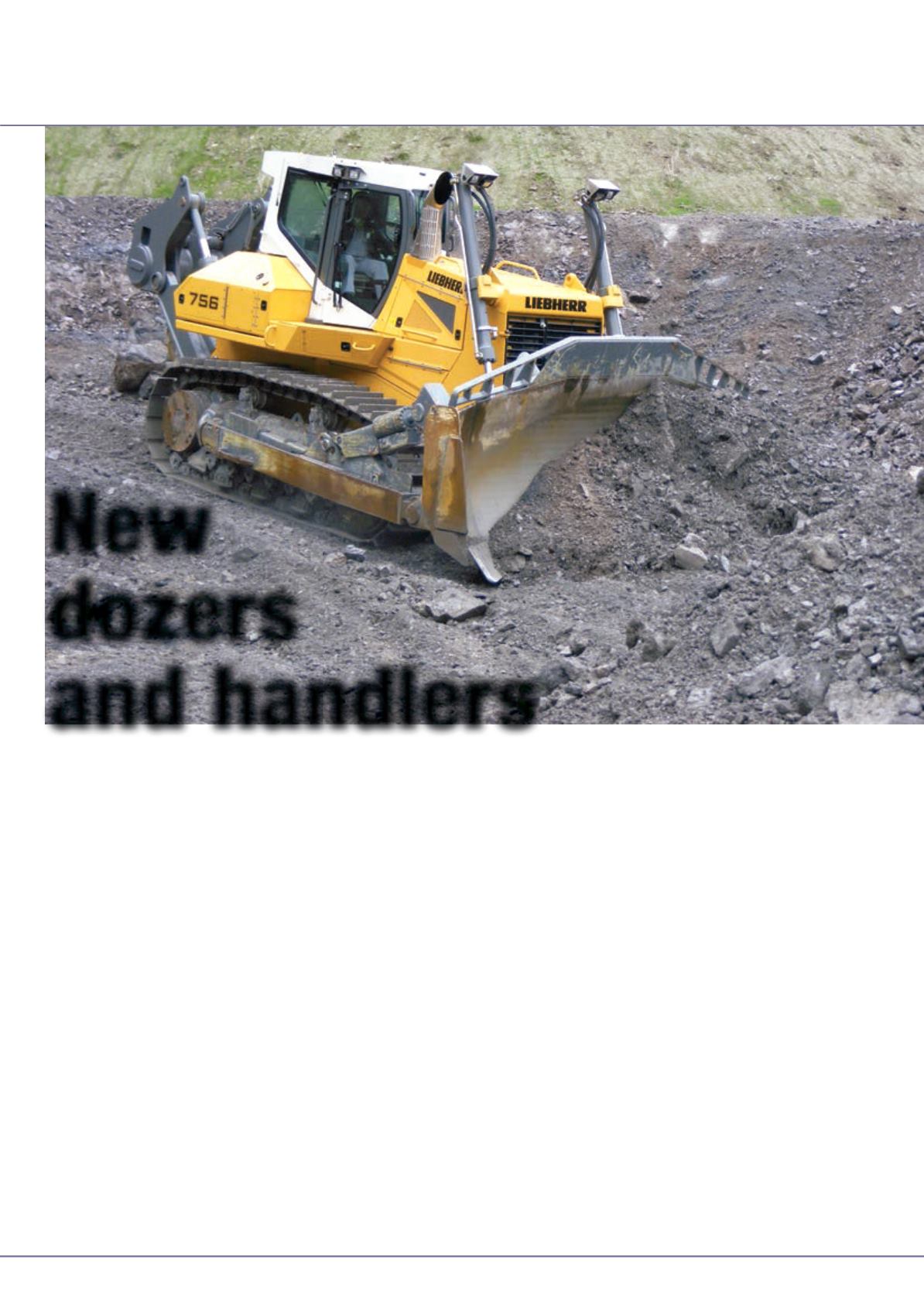

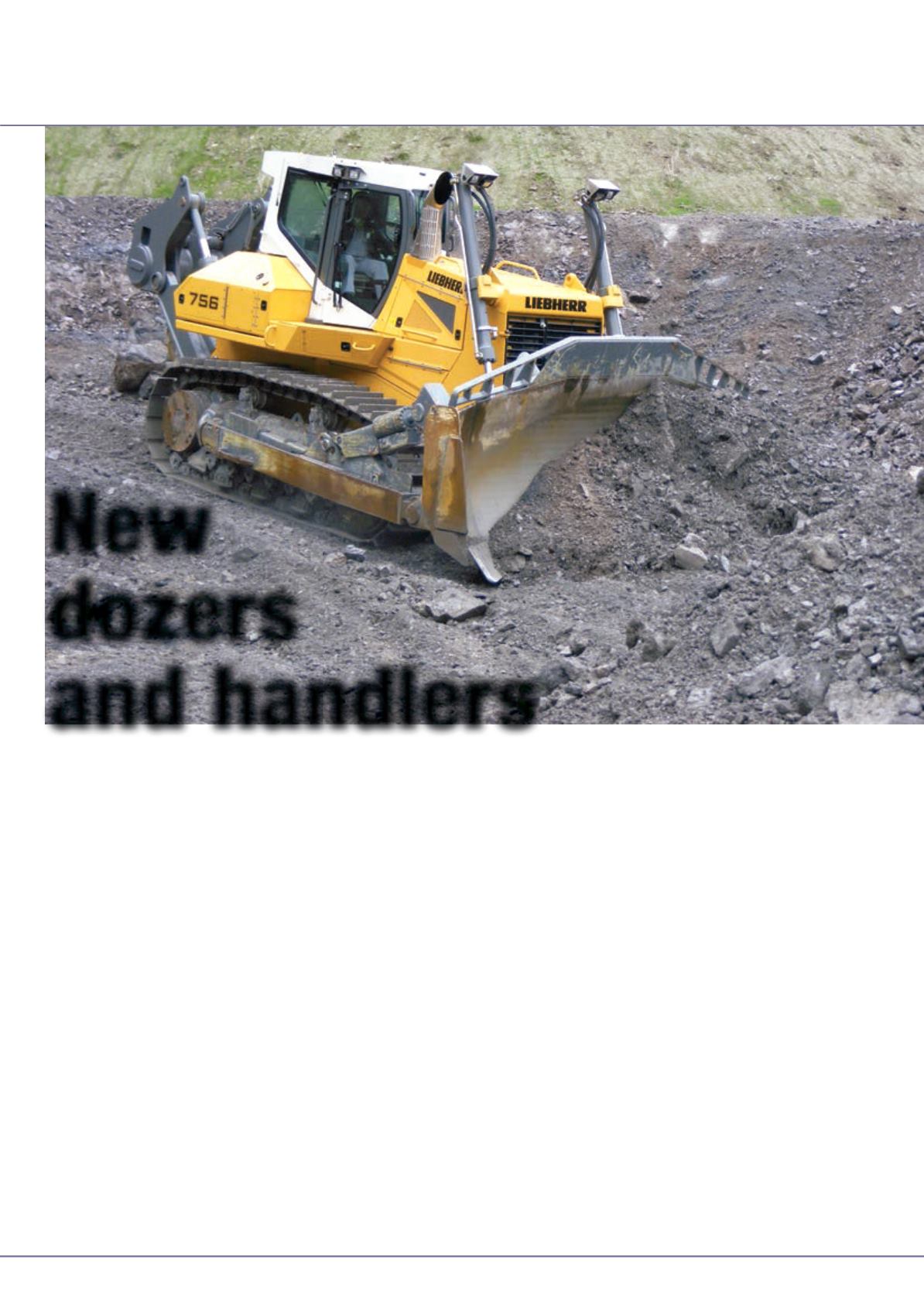

Liebherr

L

iebherr’s plant inTelfs,

Austriamanufactures the

group’s range of dozers,

crawler loaders and telescopic

handlers.Development work at

the factory has continued a pace

this year, withnew additions to

Liebherr’sGeneration 6dozers now

rolling out, alongwith brandnew

telescopic handlers, whichwill add

significantly to the range Liebherr

offers.

As far as the dozers are concerned,

Liebherr has now released Stage

IV/Tier 4Final-compliant versions

of the two largestmachines in its

Generation 6 range. At around

30 tonnes weight andwith a 185

kW engine, the PR 746Litronic

equates to aCaterpillarD7dozer,

while the 40 tonne class, 250 kW

PR 756Litronic competes with the

D8.They join the PR 736Litronic,

whichwas the firstGeneration 6

machine to be released inApril.

As withmany other Liebherr

machines, the company uses

hydrostatic drives for its dozers. It

Liebherr’s plant in

Telfs, Austria is busy

renewing its offering,

withmoreStage IV-

compliant dozers and

an expanded range of

telescopic handlers.

ChrisSleight

reports.

operator comfort.There is a touch

screen control in the cab to access

all themajor functions and the

newmachines alsohave anupdated

ECO functions, whichparticularly

helps fuel efficiency inmedium and

light work.

Liebherr’s LiDAT telematics

system is standard.TheGeneration

6machines can also be factory-

fittedwith kits to accept themajor

brands ofmachine control system

available on themarket.

Telehandler expansion

Liebherr entered the telehandler

segment in 2007with fourmodels

offering vertical reaches of 10m to

13m. It is now planning a large,

phased expansion of themachines

it offers, asmanaging director

of Liebherr-WerkTelfs,Martin

Längle explained.

“Based on the experience in the

industrial segment and after a

thorough analysis of bothmarkets,

Liebherr decided to enter the high

volume 7m class.Our engineers

New

dozers

and handlers

says the use of this technology over

a traditional transmission and axles

has a number of advantages.

Acceleration to top speed is

smooth and continuous, withno

gear changes.Mounting amotor

on each tracknot onlymeans high

ground clearance, as there is no

axle, and also allows the tracks to

counter-rotate, so the dozers can

more or less turn on the spot.

Liebherr also says the hydrostatic

drive helps with fuel economy, as

the engine is kept at constant revs

at itsmost efficient point, with

other on-board systemsmanaging

travel and other functions.The

hydrostatic system also acts as a

brakewhen required, and canhold

the dozer still on steep inclines.

Liebherr hasmet the

requirements of Stage IVwith the

use of selective catalytic reduction

(SCR) as after treatment on its

6-cylinder engines, which are used

on both the PR 746 andPR 756.

Themachines’ cabs and controls

have been redesigned for greater

The new PR 756 being

put through its paces.